- Robotics - Automation - Industrial IT

- Industrial Software

- Control software

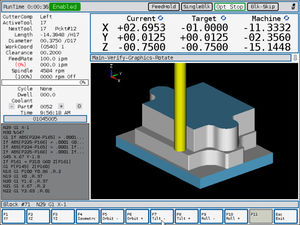

- Milltronics Manufacturing

Control software ChipBoss™ for CNC machines

Add to favorites

Compare this product

Characteristics

- Function

- control

- Applications

- for CNC machines

Description

New optional software from Milltronics uses proprietary algorithms to calculate toolpaths and control the maximum allowable cutter engagement resulting in:

• Faster cycle times

• Better tool life

• More accurate parts

• Cycle times can be reduced by as much as 50% (or more) and 3-5 times better tool life

• Part accuracy can improve through reduction in tool deflection

ChipBossTM uses trochoidal milling strategies with deeper depths of cut and smaller step overs:

• Feed rates can be much higher than what conversational users are used to experiencing.

• Reduces the number of times a machine needs to accelerate and decelerate – “less wear and tear”

• Includes “Rest Roughing” – automatically calculates the areas to be machined and uses a smaller cutter to get just those areas that can’t be cut with larger tool, saving even more time.

How it Works

To begin with, consider first a typical conversational program:

• To avoid overheating the tool the operator typically uses multiple incremental depth cuts

• Uses slower feeds and speeds

• Often needs to use coolant (not always desired)

• With incremental depth cuts, usually only the tip of the tool is used

• The majority of the useable flute length is being wasted

Rest Roughing

Use Rest Roughing to further improve cycle times:

• Select a large diameter tool to efficiently remove bulk material, followed by a smaller diameter tool to get what the larger tool can’t reach

• Rest cycle does just the “rest” areas, no need to re-cut entire profile

• All automatic – just select from drop down menu and the software calculates everything for you

Catalogs

No catalogs are available for this product.

See all of Milltronics Manufacturing‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.