- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

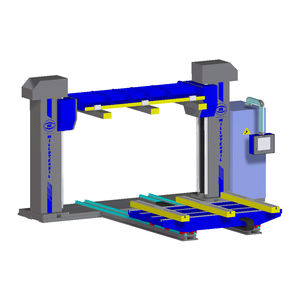

Oleodynamic press MIL3525 die-spottingtesttryout

Add to favorites

Compare this product

Characteristics

- Operation

- oleodynamic

- Function

- die-spotting, test, tryout, fusing

- Structure

- column type, 4-column, rotating table, compact

- Control

- PLC-controlled

- Other characteristics

- with pressure regulator

- Applications

- for industrial applications, for the automotive industry, for plastics, for automotive parts, repair

Description

The MIL / compact series spotting presses are a recent innovation to optimise adjusting in the die casting sector. They feature an extensible plate exit on the backside towards the long side between the columns. In this sector, moulds are relatively small, but they are often equipped with internal sliding beds that are driven by very long auxiliary cylinders that considerably increase the mould total overall dimensions.

Carrying out adjusting operations on a smaller and therefore cheaper press with consequent reduction of investment amortisation times;

Handling of moulds with very long auxiliary cylinders without the need to disassemble them, with consequent considerable time saving;

Possibility to manufacture the plate backside exit with special travels.

Catalogs

No catalogs are available for this product.

See all of Millutensil‘s catalogsExhibitions

Meet this supplier at the following exhibition(s):

Related Searches

- Millutensil industrial press

- Millutensil hydraulic press

- Automatic press

- Millutensil joining press

- Millutensil column type press

- Millutensil PLC-controlled press

- Millutensil 4-column press

- Millutensil press for the automotive industry

- Millutensil press for industrial applications

- Millutensil compact press

- Millutensil plastic press

- Millutensil automotive part press

- Riveting press

- Millutensil repair press

- Millutensil test press

- Millutensil press with movable table

- Electronic press

- Millutensil press with pressure regulator

- Rubber press

- Millutensil die-spotting press

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.