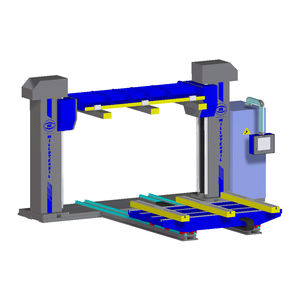

Oleodynamic press MIL305die-spottingtesttryout

Add to favorites

Compare this product

Characteristics

- Operation

- oleodynamic

- Function

- die-spotting, test, tryout, fusing

- Structure

- column type, 4-column, rotating table, with movable table

- Control

- PLC-controlled

- Other characteristics

- with pressure regulator

- Applications

- for industrial applications, for the automotive industry, for automotive parts, repair

- Force

4,000 kN, 5,000 kN

- Table length

2,400 mm

(94 in)

Description

The die & mould spotting presses of the traditional MIL/CLASSIC series feature the extensible plate exit on the side, towards the short side of the distance between columns. They are typically used in the plastics, rubber and die casting sectors.

This solution allows tilting on the extensible plate short side up to 70° on both sides. In this version, the upper plate, too, is tilted on the short side from 100° to 180°.

The MIL/CLASSIC series provides great advantages compared to other solutions with long side rotation

Better working ergonomics, granting the operator to have easy access to any mould part without the use of platforms;

Much shorter total press height above ground, which often reduces excess costs for foundations;

Wide base press structure with greater stability;

The two mould-halves are located on the same side, so operators have an overview of the whole mould and can work more comfortably

MIL COMPACT SERIES

The MIL/COMPACT series die & mould spotting presses are a riveting innovation to optimize adjustments in the die casting sector.

They feature the extensible plate exit on the backside, towards the longest side of the gap between the columns. In this sector moulds are relatively small, but they are often equipped with internal sliding beds that are driven by very long auxiliary cylinders, considerably increasing the total dimensions of the mould overall.

Therefore, the MIL/COMPACT series provides significant benefits:

Carrying out adjusting operations on a smaller and therefore cheaper press with subsequent reduction of the investment amortization period;

Handling of moulds with very long auxiliary cylinders without the need to disassemble them,

Catalogs

Die & mould spotting presses MIL

40 Pages

Related Searches

- Industrial press

- Hydraulic press

- Automatic press

- Assembly press

- PLC-controlled press

- Drilling press

- Four column press

- Press for the automotive industry

- Press for industrial applications

- Compact press

- Plastic press

- Automotive part press

- Repair press

- Riveting press

- Test press

- Press with movable table

- Rubber press

- Electronic press

- Press with pressure regulator

- Die-spotting press

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.