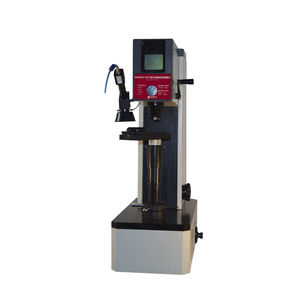

Rockwell hardness tester MHRX seriesbenchtopmetalfor quality control

Add to favorites

Compare this product

Characteristics

- Type

- Rockwell

- Mounting

- benchtop

- Product applications

- metal, for quality control, parts

- Other characteristics

- digital

Description

Mitech MHRX-45-150DX Digital Double Rockwell Hardness Tester

Measuring range:HRA:20-96、 HRB:20-100、HRC:20-70、 HRD:40-77、 HRE:70-100、HRF:6

Resolution Accuracy:

Communication storage:

Working time:

Main unit weight:

Dimensions:540*230*710mm

Package dimensions:61*53*78cm

Total weight:100kg

Product Overview

Mitech MHRX-45-150DX Digital Double Rockwell Hardness Tester, based on the mechanical principle of conical diamond or hard alloy indenter pressing into the sample surface to produce indentation, realizing the material hardness measurement by measuring the depth of the indentation. Capable of inspecting the finished or semi-finished parts of the machined sample, it is suitable for high accuracy hardness testing for batches parts with various metal or non-metallic materials. According to statistics, Rockwell hardness testing is the most widely used hardness testing method in metal processing industry, which utilization ratio is more than 70%. With novel appearance, stable performance and integration of electro mechanical integration and touch screen, it can be tested on the hardness of all rockwell and surface rockwell scale. It is widely used in metal processing and manufacturing, various metal material’s failure analysis and other fields like colleges and research institutions, and it is the sophisticated detection equipment to test the Rockwell hardness of metal and other materials.

Function & application

- Used for quality control in metal processing manufacturing

- Used for failure analysis testing of metallic materials;

- Demonstration experiment for education and teaching in Colleges and Universities;

Catalogs

No catalogs are available for this product.

See all of Mitech‘s catalogsRelated Searches

- Indentation hardness tester

- Benchtop indentation hardness tester

- Digital hardness tester

- Thickness measuring machine

- Rockwell indentation hardness tester

- Brinell indentation hardness tester

- Vickers indentation hardness tester

- Automatic indentation hardness tester

- Portable indentation hardness tester

- Metal indentation hardness tester

- Steel indentation hardness tester

- Coating thickness gauge

- Digital display thickness gauge

- Hydrometer

- Fault detector

- Ultrasonic thickness measuring machine

- Aluminum indentation hardness tester

- Handheld thickness gauge

- Analog hardness tester

- Shore hardness tester

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.