Monitoring software RT ToolBox3programmingrobot programmingsimulation

Add to favorites

Compare this product

Characteristics

- Function

- monitoring, programming, robot programming, simulation, engineering, creation, editing, verification, debugging, preventive maintenance

- Applications

- battery

Description

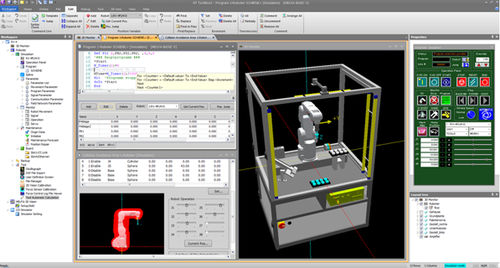

This PC based robot programming software is used with all Mitsubishi Electric robots. Programming, monitoring and debugging are some of the features of the powerful software package.

RT ToolBox3 is the programming environment for all Mitsubishi Electric robots. It enables users to create programs in minutes using the MELFA BASIC IV, V and VI robot languages (varies depending on the model).

Total engineering support

RT ToolBox3 supports all processes from system startup to debugging and operations, including programming and editing, verification of the scope of operations prior to introducing a robot, estimation of tact time, robot debugging prior to startup, and monitoring of robot conditions and malfunctions during operations.

From programming to startup and maintenance

Robot movements, operational status, input signals, and servo conditions can be monitored easily thanks to the preventive maintenance forecast function that notifies users of the robot’s greasing time and battery life-time. An assistance function for position recovery in the event of trouble is shortening the break down time.

Simulation functions

RT ToolBox3 simulates created programs for up to eight robots. Robot movements can be verified and tact time can be measured. Such simulation functions are also effective for preliminary examinations. Furthermore, signals can be linked to GX Works3 for easy creation of line simulators.

Catalogs

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.