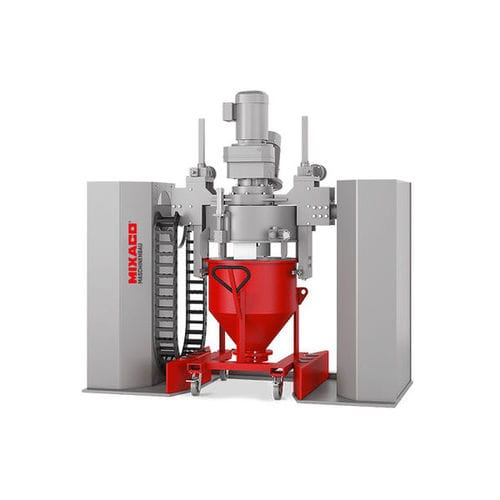

The MIXACO container mixer Multitool™ is ideal for the careful mixing of temperature-sensitive materials. An innovative mixing concept with new tools and a special process enables mixing without temperature increase.

One Machine Does It All: The MIXACO container mixer Multitool™ is ideal for the careful mixing of temperature-sensitive materials. An innovative mixing concept with new tools and a special process enables mixing without temperature increase. Specially-designed tools create different material flows in the mixing chamber, significantly reducing frictional warming of the product. The temperature increase is only one-tenth of that found in conventional mixers.

The outer mixing tool, or conveyor tool, continually transports material (primary flow) into the operating area of the chopper drive, which creates a localized but highly dynamic secondary flow. The combination of mixing flows ensures that rapid mixing and optimum dispersion are achieved.

The MIXACO Multitool™ is a container mixer with numerous benefits for internal logistics and production workflows, as it can be seamlessly integrated in work processes.

All Benefits at a Glance

* Minimal product heating

* Optimum homogenization

* Adjustable comminution rate

* No fusion or adhesion of material

* Reduced cleaning time

* User-friendly, ergonomically optimized cleaning in preconfigured cleaning position

* Material transport in mixing container for greater logistical efficiency

* High flexibility

* Wide range of tool and motor combinations enable use in many different mixing tasks

* Low energy consumption