- Production Machines

- Other Manufacturing Equipment

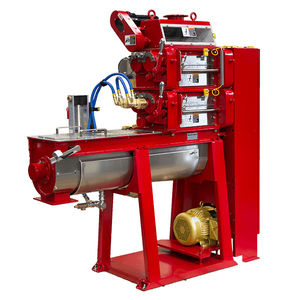

- Roller mill

- Modern Process Equipment Corporation

Roller mill IMD 800 serieshorizontalfor coffeestainless steel

Add to favorites

Compare this product

Characteristics

- Technology

- roller

- Orientation

- horizontal

- Product applications

- for coffee

- Other characteristics

- stainless steel, variable speed, high-capacity

- Output

1,475 kg/h, 3,600 kg/h

(3,252 lb/h, 7,937 lb/h)

Description

IMD 800 Series

MODEL IMD 800 SERIES COFFEE GRANULIZER * IMD 89 - TWO (2) GRINDING SECTIONS * IMD 889 - THREE (3) GRINDING SECTIONS

Application

Espresso (200 – 450 μm): Up to 3,250 lb/hr (1,475 kg/hr)

Filter (500 – 1,000 μm): Up to 8,000 lb/hr (3,600 kg/hr)

Capacity

Up to 8,000 lb/hr (3,600 kg/hr)

Sections

2 or 3

Product Description

The IMD 800 Series Granulizer is the world’s most technically advanced coffee grinder, producing up to 4,000 kg/hr of ground coffee to the highest tolerances and most exact specifications. A central element of the IMD 800 is the recipe-driven PLC control system, which monitors and controls all aspects of the grind size and density control with “real-time” performance feedback. Modern features such as water-cooling, real-time density control and bimodal grinding make the IMD 800 the world’s most popular high-capacity industrial coffee grinder.

Features

- Variable speed rotary power feeder

- Independent Motor Drives (IMD) for each grinding section

- Integrated normalizer with density control and chaff reduction

- Water-cooled rolls and normalizer

- Automated control system with precision grind size and density control

- Dust-tight construction

- Oversized doors for easy cleaning

- High hardness rolls for maximum roll longevity

Available Options

- Integrated magnet and pneumatic slide gate

- Stainless steel or electroless nickel construction

- Extreme hardness roll coatings

- Gas-tight or hermetically-sealed design

- Closed-loop water chiller

- Internal vibrators to eliminate internal coffee accumulation

- Intelligent “RT” density control system

Catalogs

IMD_800

2 Pages

Other Modern Process Equipment Corporation products

INDUSTRIAL

Related Searches

- Grinding mill

- Horizontal grinding mill

- Vertical grinding mill

- Food lump breaker

- Rotor lump breaker

- Waste lump breaker

- Roller grinding mill

- Mill for the pharmaceutical industry

- Laboratory grinding mill

- Stainless steel grinding mill

- Powder grinding mill

- Metal mill

- High-speed grinding mill

- Automatic grinding mill

- Disc pulverizer

- Ultrafine grinding mill

- Variable speed grinding mill

- Large grinding mill

- Heavy-duty mill

- Coffee grinding mill

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.