Each company designs the incoming goods individually, so it is of utmost importance to analyze the process and to identify potential for improvement. As a specialist in the field of incoming goods, we offer hardware as well as software-based solutions for customer-specific processes. Thus, the incoming goods scanner can be deeply integrated into the processes and thus offers the best combination of economy and security.

TRANSFORMATION OF THE DATE CODE

The manufacturers of the components encode their production date on the roll.

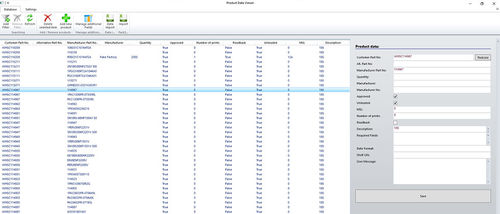

If you want to use this date to calculate, for example, the durability of the component, so you have to convert this into a “real” date. The label software now offers these possibilities. By the option to deposit the DateCode format for each article, the read date can be automatically converted accordingly. This converted date can then be used in all following systems to ensure the optimal use of the components. The same applies to other code types in date format.

EXTENDED USER MANAGEMENT

Scan processes can now be performed operator-related. Extensive rights management allows critical processes to be handled by authorized personnel only.

Up to six freely definable rights can also be individually adjusted and added. All processes can be logged. This way, scans and other operational activities are assigned to individual operators.

BLOCK PRODUCTION BATCHES WITH THE

“REJECTED BATCHES DATABASE“

If a faulty component batch has been delivered, it is important that this batch never returns to production. A new database makes it possible for MODI to block these batches and thus prevent their storage.