- Machine-tools

- Machining Center

- 4-axis machining center

- Modig Machine Tool

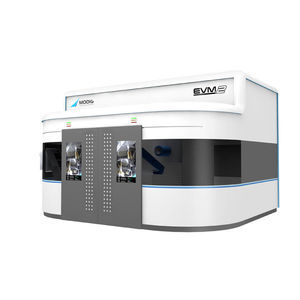

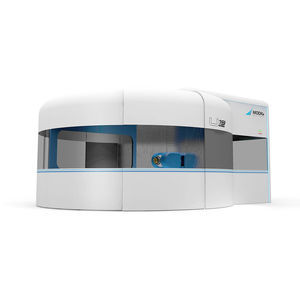

5-axis CNC machining center HHV34-axishorizontalwith rotary table

Add to favorites

Compare this product

Characteristics

- Number of axes

- 5-axis, 4-axis

- Spindle orientation

- horizontal

- Structure

- with rotary table

- Machined material

- for aluminum, for steel, for composites

- Spindle mount

- HSK A-63

- Applications

- for the automobile industry, for titanium

- Other characteristics

- automated loading/unloading

- X travel

1,500 mm

(59.06 in)- Y travel

420 mm

(16.54 in)- Z travel

260 mm

(10.24 in)- Rotational speed

Max.: 30,000 rpm

(188,496 rad.min-1)Min.: 0 rpm

(0 rad.min-1)- Work feed X-axis

Max.: 60,000 mm/min

(39 in/s)Min.: 0 mm/min

(0 in/s)- Work feed Y-axis

Max.: 60,000 mm/min

(39 in/s)Min.: 0 mm/min

(0 in/s)- Tool-changing time

8 s

Description

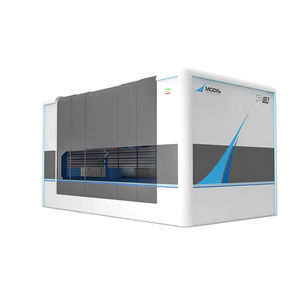

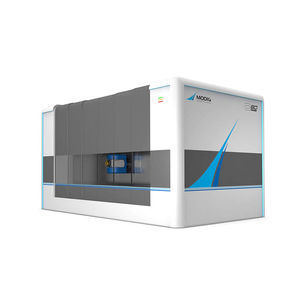

The HHV (Horizontal High Velocity) was developed in close cooperation with the world’s largest aircraft manufacturers. Since its introduction, it quickly became the first choice of top performing machine shops.

The HHV is a universal machining center for bar or extrusion components. It is ideal for limited production runs, nesting, or high-volume production. Raw material is loaded from the left side into the machine, the HHV automatically pulls the raw material into position for machining and delivers finished parts into a part catcher. Instead of cutting raw material into specific lengths, the HHV handles uncut bars and extrusions. The benefit of making many parts from the same size bar or extrusion is: reduced setup time, no workholding and a significant reduction in cycle time. Standard machining often requires multiple setups. The HHV machines parts complete in one setup, with no workholding.

Your machining cycle time at the process design stage: up to 50% faster machining time over conventional processes, better than 95% machine uptime, and, true Lean and Green production.

HHV 2 and HHV 3 designates the number of rotary tables.

HIGHLIGHTS

Bar and extrusion machine in one

Better chip flow – from horizontal machining

Complete parts in one setup

Reduced cycle time up to 40-70%

Material waste reduction

High production rate capabilities

Angle head machining possibilities

Roughing, semi-finish and finishing mode

A small footprint

Low fixture and tooling costs

Modular workholding designs for setup elimination

Different part programs on the same extrusion or bar (nesting)

No special foundation required

Full automation options available

VIDEO

Catalogs

No catalogs are available for this product.

See all of Modig Machine Tool‘s catalogsRelated Searches

- CNC machining center

- Vertical CNC machining center

- 3-axis CNC machining center

- Precision CNC machining center

- 5-axis CNC machining center

- Rigid CNC machining center

- High-performance CNC machining center

- Gantry CNC machining center

- Column type CNC machining center

- High-productivity CNC machining center

- Aluminum CNC machining center

- Horizontal CNC machining center

- CNC machining center with pallet changer

- BT 40 CNC machining center

- Machining center for the automobile industry

- CNC machining center with rotary table

- 4-axis CNC machining center

- 60 tools CNC machining center

- Universal CNC machining center

- CNC machining center with moving table

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.