Process control software PRODUCAT® IIautomationmanagementdata exchange

Add to favorites

Compare this product

Characteristics

- Function

- management, automation, process control, data exchange

- Applications

- for the packaging industry

- Type

- real-time

Description

Maximum security. Intelligent process control technology.

The Möllers Packaging Technology systems' management comprises various modules that operate independently and fully automatically. The work processes within the machine management are monitored, documented and evaluated.

We define the interfaces for the data exchange to superior and subordinate systems.

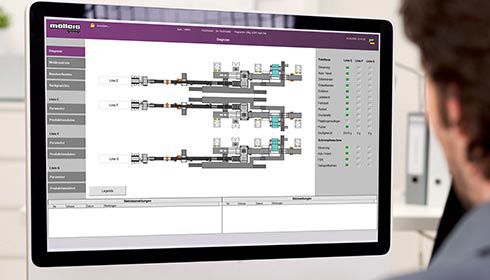

The functions of the machines within the line are visually enhanced - for easy handling, fault diagnosis and active monitoring of the safety circuits: Safety concept. Each control circuit works autonomously - intrinsically safe and in contrast to the surrounding environment.

This safety concept - combined with the operational ease of the machine - allows the operator to react immediately to critical situations.

Möllers Packaging Technology: the measurement and optimization tool PRODUCAT® II

PRODUCAT® II, thanks to self-explanatory touchscreen icons is so simple in its handling that it significantly contracts training times for the operator. When trouble-shooting, each deviation is notified and the component affected is displayed. This contracts the search decisively – and as a result, possible Full Line downtime.

With PRODUCAT II we make a software tool available to our customers in order to measure plant efficiency precisely and to define losses. PRODUCAT II actively searches for fault sources and captured them in a log:

• Documents downtimes

• Measures time and plant availability

• Records bag per hour output

• Increases weight accuracy

• Notes bag breakages

• Mirrors consumption figures

Catalogs

No catalogs are available for this product.

See all of Möllers‘s catalogsRelated Searches

- Automation software solution

- Management software solution

- Analysis software solution

- Real-time software solution

- Monitoring software solution

- Optimization software solution

- Safety software

- Production software solution

- SCADA software

- Process control software solution

- Data exchange software solution

- Software for the packaging industry

- OEE software

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.