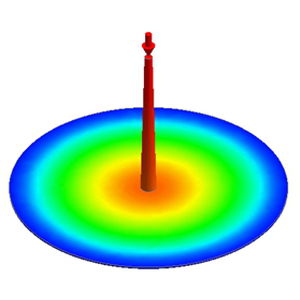

Moldex3D Injection Compression visualizes compression during filling or packing. Injection of the plastic melt in the molding compression phase is done sequentially and simultaneously with the integrated control interface. It allows adjustment of various compression conditions by users to match real processing parameters. It also analyses the performance of pressure and volumetric shrinkage. This helps users in determining suitable molding material and processing environments for improved manufacturing.

Moldex3D Injection Compression ensures lower injection pressure, molecular orientation and warpage. It helps in even distribution of pressure and volumetric shrinkage. Overpacking and material breakage are eliminated. It provides better venting and degree of reproduction. It also ensures lower cycle time.