- Robotics - Automation - Industrial IT

- Industrial Software

- Simulation software

- Moldex3D, CoreTech System Co., Ltd.

Injection molding simulation software Opticsoptical3D

Add to favorites

Compare this product

Characteristics

- Function

- injection molding simulation

- Applications

- optical

- Type

- 3D

Description

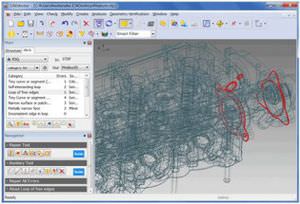

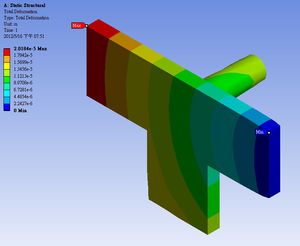

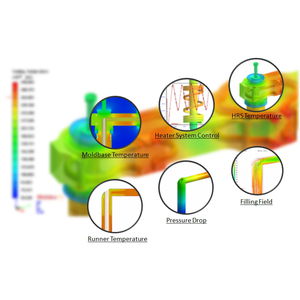

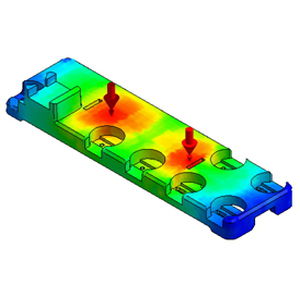

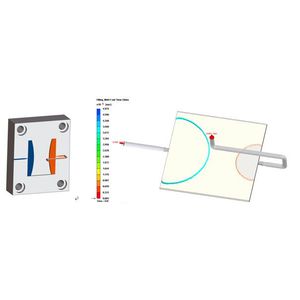

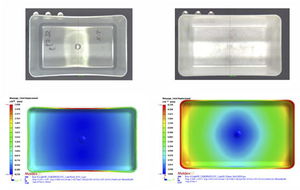

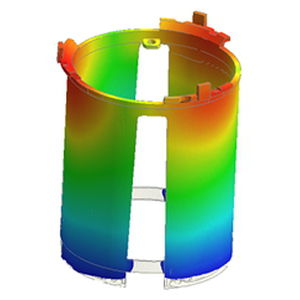

Injection molded optical plastics, widely used in 3D applications, have become smaller and lighter. The flow-induced anisotropic property would be significant in smaller filling cavities. As a result, key optical issues, such as birefringence, retardation, or polarization, would be a bottleneck in the design-to-manufacturing process. Based on the three-dimensional filling analysis and the viscoelastic analysis, Moldex3D Optics helps designers visualize the optical performance and evaluate process conditions. Furthermore, integrated with CODE V, users are allowed to export the deformed shape and refractive distribution into CODE V for design verification and optimization.

Catalogs

Other Moldex3D, CoreTech System Co., Ltd. products

Solution Add-on

Related Searches

- Management software solution

- Analysis software solution

- Process software solution

- Windows software solution

- Computer-aided design software

- Online software

- Design software solution

- 3D software solution

- Simulation software

- Visualization software solution

- Creation software

- Optimization software solution

- Modeling software

- Calculation software

- Internet-based software

- Flow software

- Verification software

- Data exchange software solution

- 2D/3D software

- Viewer software

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.