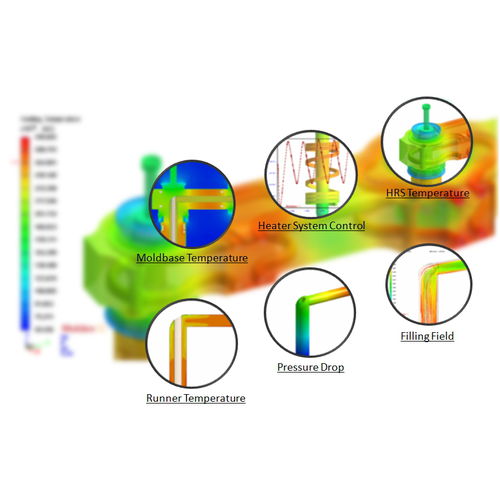

Hot runner solutions have been widely applied in various injection molded plastics, such as bumpers, automotive, or LCD/TV panels. The advantages include material and energy saving, shorter cycle time, reduced injection and clamping force, etc. However, a hot runner system is comparatively more complex and commonly faced with the challenge of temperature control and the risk of thermal degradation of plastic materials. Moldex3D enables designers to simulate the hot runner molding process and improve the heating efficiency. Users can evaluate the effects of process conditions, predict potential defects, and achieve design and process optimization.