- Robotics - Automation - Industrial IT

- Industrial Software

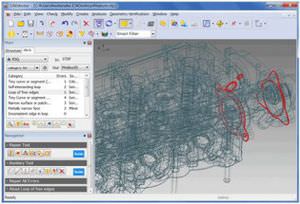

- Analysis software

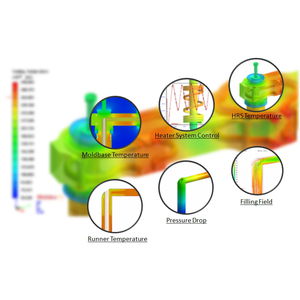

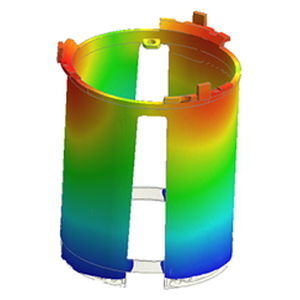

- Moldex3D, CoreTech System Co., Ltd.

FEA mechanical fatigue analysis software Underfill

Add to favorites

Compare this product

Characteristics

- Function

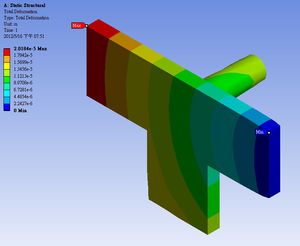

- FEA mechanical fatigue analysis

Description

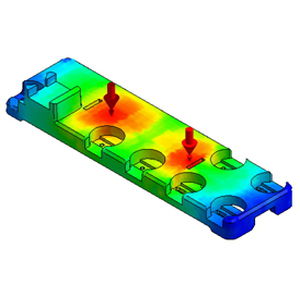

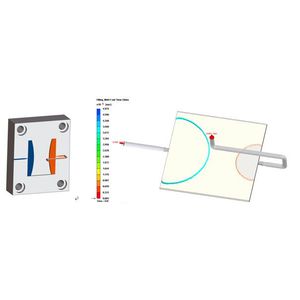

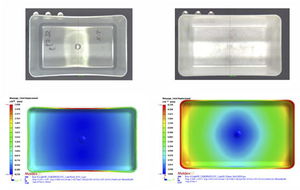

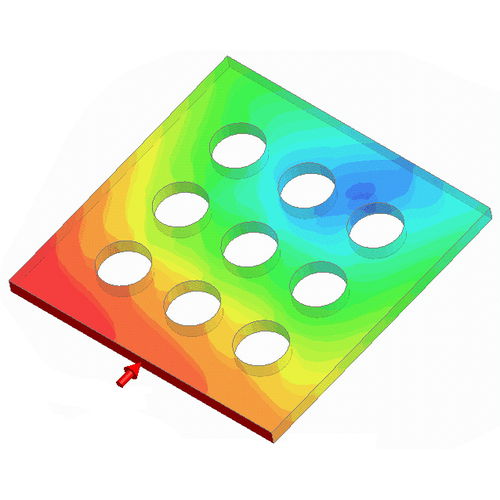

Applicable IndustriesIC PackagingEnhancements of Underfill MoldingDue to low thermal expansion coefficient of flip chip materials, deformation often occurs in a thermal cycle. The unexpected deformation will cause mechanical fatigue and lead to solder defects or breaking problems. Therefore, Underfill Molding has been developed to increase the quality reliability of flip chip.Challenges in Underfill Simulation Calculate the surface tension force accurately Track the stability of melt advancementExplore Moldex3D’s Capabilities Visualize the surface tension behavior among encapsulant, bumps and substrate Visualize the filling pattern of the dynamic dispensing process

Catalogs

Other Moldex3D, CoreTech System Co., Ltd. products

Solution Add-on

Related Searches

- Management software solution

- Analysis software solution

- Process software solution

- Windows software solution

- Computer-aided design software

- Online software

- Design software solution

- 3D software solution

- Simulation software

- Visualization software solution

- Creation software

- Optimization software solution

- Modeling software

- Calculation software

- Internet-based software

- Flow software

- Verification software

- Data exchange software solution

- 2D/3D software

- Viewer software

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.