- Robotics - Automation - Industrial IT

- Industrial Software

- Design software

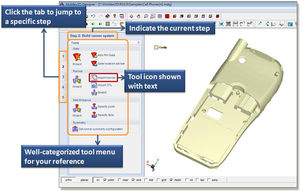

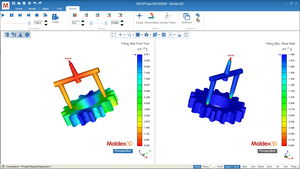

- Moldex3D, CoreTech System Co., Ltd.

Analysis software Warpdesignoptimizationflow

Add to favorites

Compare this product

Characteristics

- Function

- analysis, design, optimization

- Applications

- flow

- Type

- 3D

Description

Warp

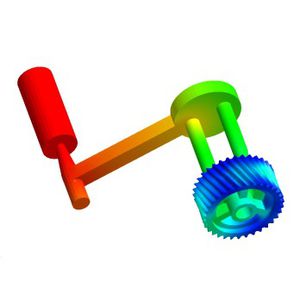

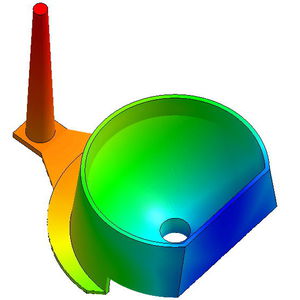

Moldex3D Warp allows users to perform dynamic warpage analysis on thick parts and those parts that have extreme thickness changes. With Warp, users can easily validate part deforming ratio of shrinkage effect and efficiently identify warpage causes. For fiber-filled material, Warp incorporates fiber composite theories and fiber orientation results to predict its anisotropic shrinkage, residual stress, and material viscoelasticity effects on warpage. Furthermore, Warp can link through FEA Interface module, which integrated with most leading structure software to perform more realistic structural analysis.

Capabilities

Evaluate final part shape before actual molding

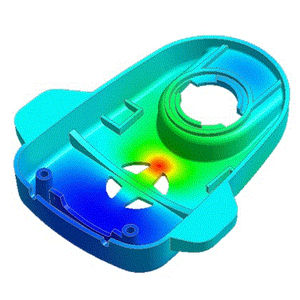

Evaluate unbalanced cooling effect on warpage

Evaluate volumetric shrinkage effect on warpage

Evaluate in-mold constraint effect on warpage

Evaluate thermal-induced residual stress and moldbase thermal deformation effect

Provide flatness to evaluate the warpage of surface appearance

Features

Part warpage analysis

Calculate final part shape due to material shrinkage as the temperature and pressure changes from the process settings to room conditions.

Residual stress analysis

After part ejection, the part shrinks and deforms to an equilibrium shape. At this moment, the remaining stress inside the part is called process-induced residual stress

Calculate residual stresses developed during the entire molding cycle, including effects of temperature and pressure distributions, material orientation and geometric features

Catalogs

Other Moldex3D, CoreTech System Co., Ltd. products

eDesign

Related Searches

- Management software solution

- Analysis software solution

- Process software solution

- Windows software solution

- Computer-aided design software

- Online software

- Design software solution

- 3D software solution

- Simulation software

- Visualization software solution

- Creation software

- Optimization software solution

- Modeling software

- Calculation software

- Internet-based software

- Flow software

- Verification software

- Data exchange software solution

- Viewer software

- 2D/3D software

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.