- Robotics - Automation - Industrial IT

- Industrial Software

- Simulation software

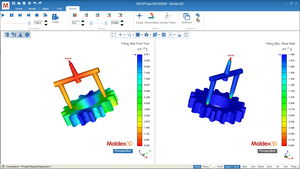

- Moldex3D, CoreTech System Co., Ltd.

Injection molding simulation software RIMprocessplastic injection process

Add to favorites

Compare this product

Characteristics

- Function

- injection molding simulation

- Applications

- process, plastic injection process

Description

Why Reactive Injection Molding?

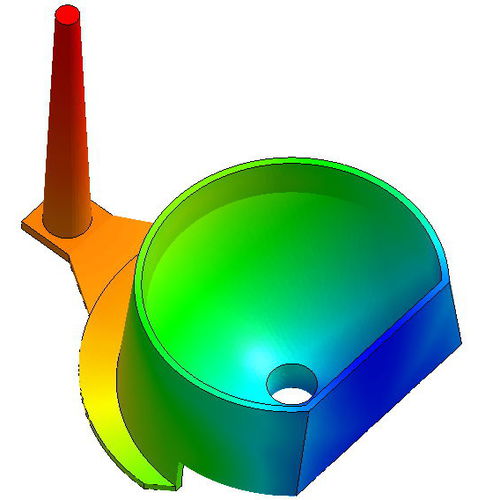

Reactive injection molding (RIM) is similar to the conventional injection molding (IM) except thermosetting materials are used. The chemical curing reaction occurs simultaneously as the resin flows during the molding process. The polymerization of RIM is usually activated after mixing under heating with or without high pressure. The advantage of RIM is that with its relatively low viscosity, resins can readily fill the cavities with large L/D ratio. The RIM can produce plastic parts with high mechanical strength because of the crosslinking in polymer structures.

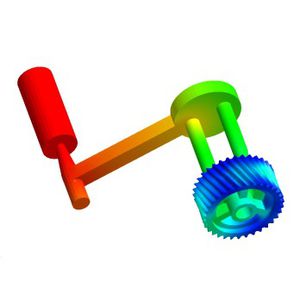

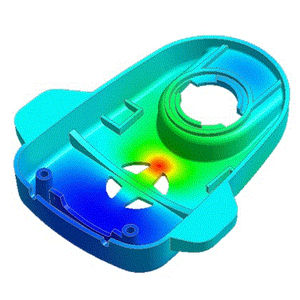

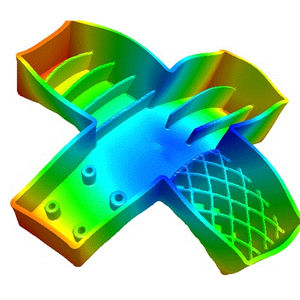

However, the thermosetting polymers are usually difficult to be recycled, and the potential problems of flashing, scorching and longer cycle time have been the main challenges of RIM. Moreover, the complicated interplay between chemical reaction, fluid flow and heat transfer bring more uncertainty on process control and optimization for RIM. Moldex3D RIM offers true 3D solutions to analyze RIM processes for thermosetting materials including unsaturated polyester, polyurethane, rubber compound, liquid silicone rubber, and epoxy molding compound. The software simulates cavity filling, curing, part warpage, fiber orientation, multi-component molding, and many other customized methods and processes.

Challenges

Part and mold design verification and optimization to reduce manufacturing cost and design cycle time.

Process optimization to increase part quality and product competitiveness

What Can Moldex3D Do?

Complete simulation modules include cavity filling, curing, part warpage, fiber orientation, multi-component process and interface to advanced structural analyses.

Catalogs

Molding Innovation

12 Pages

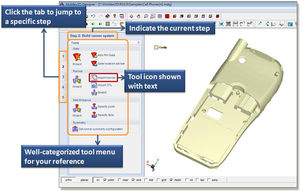

MDX3D R15 eDesign

4 Pages

Other Moldex3D, CoreTech System Co., Ltd. products

eDesign

Related Searches

- Management software solution

- Analysis software solution

- Process software solution

- Windows software solution

- Computer-aided design software

- Online software

- Design software solution

- 3D software solution

- Simulation software

- Visualization software solution

- Creation software

- Optimization software solution

- Modeling software

- Calculation software

- Internet-based software

- Flow software

- Verification software

- Data exchange software solution

- 2D/3D software

- Viewer software

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.