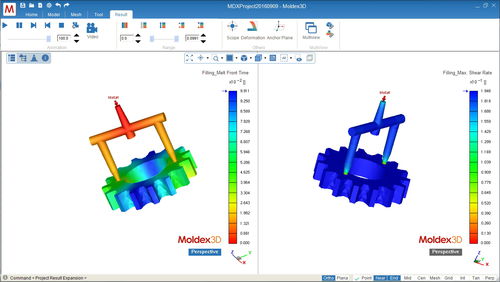

Studio

Moldex3D Studio is a comprehensive analysis platform. The intuitive interface is made with ribbon-style, and user can complete simulation workflow on the same interface. Clear icon design and integrated pre- & post- analysis function layout. It can quickly accomplish model preparation and re-meshing, and also for solver calculation and result display. When meshing, user can instantly switch the mesh mode between eDesign or BLM based on the module and license used. BLM mesh type enables to build model with fully Tetra mesh or with Boundary layer mesh (BLM). Users can generate 3D solid mesh for part and mold design more efficiently. And it can continue with F/P/C/W analysis calculation sequence after the pre-analysis setting without interruption. For a user-friendly design, there are four tree layered item list for easier modeling operation and management:

Model Tree: All the model components and groups are clearly listed. Thus users have options to select model “by group” or “by component”.

Defect Tree: All the mesh defects and the count are shown in the list and user can easily select the defect type by tree to locate and fix it.

Project Tree: All the mesh information, material data, process condition and simulation result can be checked and select to watch directly.

Material Tree: Let User specify the part and part insert material on the Tree.

Mixed Runner System

Support mixing connection of poly-surface runner and curve runner to generate solid mesh. The recommended mixed type is curve runner with poly-surface gate. The comment solid mesh is Hexa or Prism solid mesh for curve runner, and Boundary Layer Mesh (BLM) for poly-surface runner.