Automatic Fault Detection and Plant Monitoring With AI

Buildings and energy systems today often run far from their optimum. This applies not only to complete systems but also to individual components. However, suboptimal operation means more energy consumption, less user comfort and, on balance, higher operating costs.

Because energy systems and buildings are becoming increasingly complex, the manual search for the cause of a suboptimal operation is a thing of the past. IoT monitoring with artificial intelligence is now the name of the strategy in the age of digitalization.

Detect Faults in Operation Promptly

With the help of mathematical methods, faults in the operation of technical building equipment and energy plants can be detected promptly. The focus here is on pattern recognition with AI algorithms. These can analyze even extensive databases with great precision and at breathtaking speed.

Previously defined deviations of the plant signals from the mean are detected as errors. Service personnel are notified immediately via an internal alarm system.

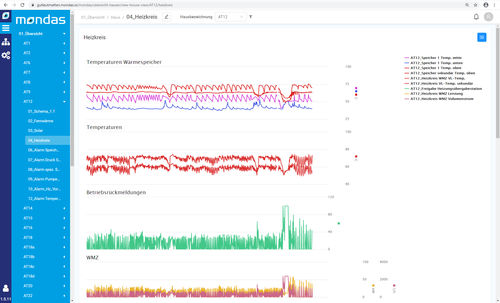

The mondas® Analytic software is characterized by a particularly fast evaluation of time series data. Temperature values, starts, oil pressure and many more are recorded and interpreted over time. Their interdependence can thus be observed and evaluated.

Mondas® is working in close cooperation with the Fraunhofer Institute for Solar Energy Systems ISE to develop the data processing algorithms. The algorithms are based on expert knowledge, machine learning methods, decision trees or a combination of these methods. Model- and rule-based methods are used for this purpose.