- Packing - Handling - Logistics

- Packing and Packaging

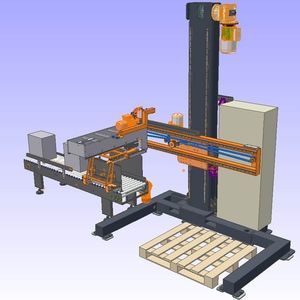

- Layer palletizer

- Mondo e Scaglione

Layer palletizer COMPACT 2007vertical operationcasefor the packaging industry

Add to favorites

Compare this product

Characteristics

- Type

- layer

- Product applications

- case, vertical operation

- Sector

- for the packaging industry

- Other characteristics

- automatic

- Throughput

15 p/min, 25 p/min

- Machine width

5,700 mm

(224.41 in)

Description

Machine suitable to palletise “American” style cases, PVC crates or bundles with product feeding from machine low part.

Features

• Preparation of the row of cases on a motorized rollers conveyor at machine in-feed.

• An electro-pneumatically controlled selector, at machine in-feed, enables cases selection in the row preparation area.

• 90° case turning device electro-pneumatically controlled to orientate product when requested by the configuration.

• A pushing unit transfers the complete row of cases positioning it on an intermediate moving platform.

• Vertical movement of the intermediate platform, to bring the prepared row at a maximum height.

• A second pushing unit electromechanically controlled, built-in machine frame in a high position, transfers the rows of cases on a platform positioned at maximum height.

• A two ways opening platform, electromechanically controlled containing the whole layer, enables the unloading of cases on the pallet.

• Empty pallet vertical lift at maximum height and pitch-to-pitch lowering at each layer unloaded.

• Strong painted steel frame, lifting axes with sliding guides in tempered steel and sphere recycle carriages with counterweight for balancing.

• Inner pallet conveyor with motorized rollers.

• “Touch-screen” display to manage machine functions, the changeover and to visualize possible anomalies.

• Machine complete of electrical installation, electrical panel and safety guards.

• Machine managed by a PLC Siemens S7.

VIDEO

Catalogs

No catalogs are available for this product.

See all of Mondo e Scaglione‘s catalogsRelated Searches

- Palletizer

- Automatic palletizer

- Case packer

- Case sealer

- Layer palletizer

- Automatic case packer

- Adhesive tape case sealer

- Cardboard box/case erector

- Multi-flap case sealer

- Automatic cardboard box/case erector

- Case palletizer

- Horizontal case packer

- Automatic case sealer

- Depalletizer

- Adhesive tape cardboard box/case erector

- Palletizer for the packaging industry

- Bottle case packer

- Vertical case packer

- Automatic depalletizer

- Hot-melt glue cardboard box/case erector

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.