- Packing - Handling - Logistics

- Packing and Packaging

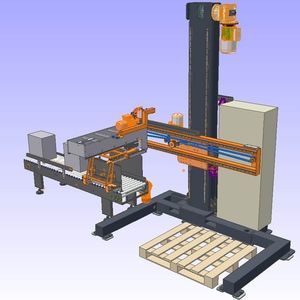

- Layer palletizer

- Mondo e Scaglione

Layer palletizer P6casecase conveyorfor the packaging industry

Add to favorites

Compare this product

Characteristics

- Type

- layer

- Product applications

- case, case conveyor

- Sector

- for the packaging industry

- Other characteristics

- automatic

- Throughput

25 p/min, 40 p/min

- Machine width

6,400 mm

(251.97 in)

Description

https://mondo-scaglione.com/download/Image/pale02-foto3.jpg

• Case conveyor with motorized rollers at machine in-feed.

• Spacers mounted between rows preparation rollers, pneumatically controlled, to create spaces

• between cases when requested by the configuration.

• 90° case turning device electro-pneumatically controlled to orientate product when requested by the

• configuration.

• Electromechanically controlled pushing unit, to transfer the rows of product and to transfer the layer

• into the palletisation head.

• Intermediate table to contain the rows of cases before their pushing inside the palletisation head.

• Palletisation head with side compacting guides electromechanically controlled and lower platform,

• with two ways opening, electromechanically controlled. This system enables to position product on the

• outer perimeter leaving empty spaces when necessary.

• Main frame with a double column on a strong base with supports adjustable in height. The column

• contains counterweights for balancing.

• Inner pallet conveyor with motorized rollers.

• “Touch-screen” display to manage machine functions, the changeover and to visualize possible

• anomalies.

• Machine complete of electrical installation, electrical panel and safety guards.

• Machine managed by a PLC Siemens S7.

VIDEO

Catalogs

No catalogs are available for this product.

See all of Mondo e Scaglione‘s catalogsRelated Searches

- Palletizer

- Automatic palletizer

- Case packer

- Case sealer

- Layer palletizer

- Automatic case packer

- Adhesive tape case sealer

- Cardboard box/case erector

- Multi-flap case sealer

- Automatic cardboard box/case erector

- Case palletizer

- Horizontal case packer

- Automatic case sealer

- Depalletizer

- Adhesive tape cardboard box/case erector

- Palletizer for the packaging industry

- Bottle case packer

- Vertical case packer

- Automatic depalletizer

- Hot-melt glue cardboard box/case erector

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.