- Products

- Catalogs

- News & Trends

- Exhibitions

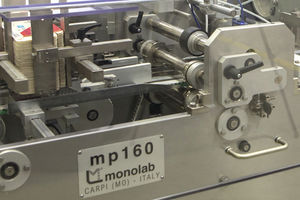

Blister packaging machine MB964PLC-controlledliquidsfor powders

Add to favorites

Compare this product

Characteristics

- Operational mode

- PLC-controlled

- Type

- blister

- Applications

- liquids, for powders

- Domain

- medical, for the pharmaceutical industry

- Other characteristics

- flexible

- Throughput

Min.: 0 p/h

Max.: 10,000 p/h

Description

MAIN ASPECT

Monolab MB964 blister mono-dose machine has been designed and patented as an extremely flexible thermoforming machine, capable of offering high quality products, achieving excellent value for money. Suitable for medium – high production batches in Pharma applications, such as production of plastic ampoules or monodose filled with syrup or powder. This design has full GMP compliance. This horizontal type manufacturing process gives the operator excellent access to all the production line, allowing a very short and economic change over of the tools and has the potential to fill liquids, gels and powder inside blisters, offering the customer a wide range of product packaging options. Including the capacity to use any material from the standard PVC, to PVC-PVDC, PET-PE, BAREX, OSMOTIC MEMBRANE, TESLIN; Available materials thickness (bottom & lid) is from 20 to 800 microns. User - friendly touch screen with Multilingual – commands and eventual PC integration;

Related Searches

- Packing machine

- Automatic packing machine

- Bell type packing machine

- Case packer

- Medical packing machine

- Packaging machine for the pharmaceutical industry

- Cartoner

- Granular packing machine

- Horizontal case packer

- PLC-controlled packing machine

- Liquids packing machine

- Blister packing machine

- Flexible packing machine

- Tablet packing machine

- Carton case packer

- Cartoner for the pharmaceutical industry

- Medical cartoner

- Blister cartoner

- Pharmaceutical products case packer

- Packaging case packer

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.