- Products

- Catalogs

- News & Trends

- Exhibitions

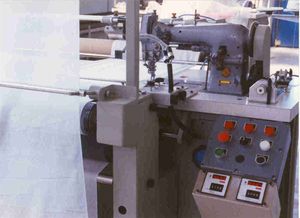

Cross hemming line 2074 TEC-09for terry fabric

Add to favorites

Compare this product

Characteristics

- Type

- cross

- Applications

- for terry fabric

Description

AUTOMATIC LINE for CROSS CUTTING AND CROSS HEMMING of terry towels.

Working cycle provides the fabric feeding to the machine with 1,2, 3 or 4 stripes (according to the width of the fabric to process), AUTOMATIC STRAIGHTENING of the product before cutting cycle, CROSS CUTTING by motorized blade, CROSS HEMMING + CROSS SEWING and unloading of the manufactured towels on a storage belt.

Double straightening system of the towel with UPPER and LOWER combs.

Chain stitch seam 1 needle, 2 threads, - with automatic stitch CONDENSATION at each corner of the product.

As option, it is possible the installation of a LOCK STITCH machines, 1 needle, 2 threads with AUTOMATIC BACK TACKING on each corner with “NO STOP” technology that grants the absence of STOPS in the production cycle for back tacking. The machine with lock stitch sewing heads is also equipped with AUTOMATIC BOBBIN CHANGER at the end of the thread on the bobbin in work.

The machine is suitable for the installation of LABELLING DEVICE in order to attach FLAT, FOLDED, BAR CODE and “German type” – HANGER in the desired position on the towels in work up to a maximum of 3 labels per side.

Possibility to install 2 additional LOCK STITCH sewing machines in combined cycle with CHAIN stitch sewing machines for BACK TACKING of the towels’ corner automatically, always with NO STOP system, that does not stop the product in work.

Possibility of working up to 4 strips of product at the same time (depending on the single width) to optimize the production of the whole line.

Other MONTI-MAC products

Hemming, overedging and binding of fabric's edges

Related Searches

- Cutting system

- Automatic cutting system

- Knife cutting system

- Fixed sewing machine

- Fabric cutting system

- Single-needle sewing machine

- Fabric sewing machine

- Automatic sewing machine

- Mounting machine

- Single-thread sewing machine

- Textile cutting system

- Automatic mounting machine

- Slitter

- Chain stitch sewing machine

- Electronic sewing machine

- Automatic slitter

- Guillotine cutting machine

- Bag sewing machine

- Overlock stitch sewing machine

- Fabric slitting machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.