- Products

- WiFi module

- montronix

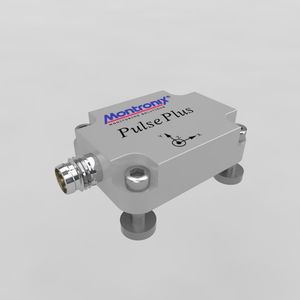

WiFi module WiFi Box Plus

Add to favorites

Compare this product

Description

The Montronix WiFi Box Plus sends the signals of the sensor Pulse Plus easily via WLAN for signal evaluation to your notebook. The built-in lithium polymer battery provides up to 15 hours of, continous independent power supply for 3D vibration measurements.

Your maintenance discovered foresighted potential defects and determines the current machine status thru comparison with the recorded "fingerprint" of your machine.

Your process technologists can optimize the cutting data effectively using the visualization software of Montronix, increase tool life as well as production and create comparative analyzes.

So you achieve maximum benefit and ROI.

Mobile 3D vibration analysis for machine condition determination and cutting data optimization

Independent use in machines and systems thanks to wireless technology

Monitoring of bearings, linear axes (ball Screws, guidance systems , etc.)

Process analyses, Prozess optimation

Condition Monitoring

With the WiFi Box Plus an extensive machine diagnostics and troubleshooting capability is possible.

These include:

Investigation of spindle bearings and other bearings (bearings state / unbalance)

Wear of ball screw drives and guiding carriage /-rails

Servo settings / errors in measuring systems

Loose in: Guides/ guiding carriage, mounting plate

Lubrication mechanics and tools

Basic reference line for rapid diagnostics of the complete machine (Machine characteristics / „fingerprint“ of the machine)

Breaks in the structure / in the machine base

External process influences from the environment

Distortions of the machine in the dynamics

Energy supply chains

Catalogs

No catalogs are available for this product.

See all of montronix‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.