- Products

- Catalogs

- News & Trends

- Exhibitions

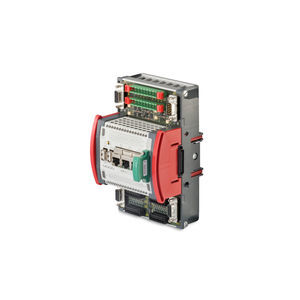

High-performance servo-actuator 220 seriesrotaryelectricelectromechanical

Add to favorites

Compare this product

Characteristics

- Movement

- rotary

- Type

- electric, electromechanical

- Technology

- spur gear

- Material

- aluminum, stainless steel

- Motor

- with brushless DC motor, permanent magnet

- Voltage

- 24 V, 20 V, 28V

- Protection class

- waterproof, robust

- Applications

- high-temperature, for the aerospace industry

- Other characteristics

- compact, high-performance, custom, small

- Rotation angle

30 °, 45 °

- Ambient temperature

Min.: -40 °C

(-40 °F)Max.: 71 °C

(160 °F)

Description

The 220 actuator is one of our most versatile designs, and it is offered in multiple variants including RS-485 digital and RC / PWM analog communications. Moog also has a design that develops twice the peak torque.

The Model 220 is a high performance rotary servo electromechanical actuator that utilizes rare earth brushless DC motors, magnetic encoder and position loop control electronics all integrated into one compact package. It is well suited for aerospace and unmanned airborne platforms due to its high performance and small envelope. It can also be used in a variety of applications as it is a self-contained servo motion solution. Although it is specified with a 7,500 hour life, Moog has tested the Model 220 actuator, meeting 16,000 hours, and the unit was still operating within specifications.

• Stainless steel spur gear train

• 8 ball bearings

• Machined aluminum structure and housing

• Stainless steel output shaft, .025 inch SAE spline

• Consult factory for custom shafts and output arms

• Brushless permanent magnet motor design

• High temperature capability

• Contactless shaft position sensor

• Differential analog position feedback

• Offered either with full RS-485 digital control

or RC / PWM analog control

• Modifiable parameters (default parameters installed at factory)

- Total electrical stroke angle

- Null position

- Direction orientation

- Torque limit

- Loss of signal - hold last position, return to zero or coast

- PID constants

- Dead band

- Telemetry scaling

- Feedforward gains

• GUI interface for programming and parameter modification

BENEFITS

• Robust structural design

• Mechanical stops

• Low weight to power performance

Catalogs

Related Searches

- Actuator

- Linear actuator

- Electric actuator

- Compact actuator

- Screw actuator

- DC actuator

- Electromagnet

- Industrial actuator

- Precision actuator

- Screw spindle actuator

- Linear electromagnet

- Standard actuator

- Hydraulic actuator

- High-performance actuator

- ISO actuator

- Servo-motor actuator

- Industrial positioning system

- Heavy load actuator

- Pull electromagnet

- Servo-actuator

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.