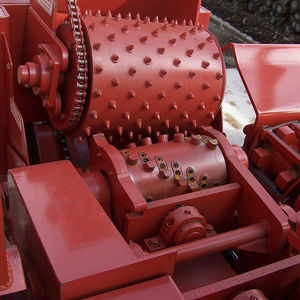

Rotary-knife debarker C series

Add to favorites

Compare this product

Characteristics

- Options

- rotary-knife

Description

will debark logs from 4" to 24" (10.2 cm - 61 cm) in diameter and up to 70' (21.3 m) in length. Using the Morbark Debarking Principle, the C series is effective in debarking hardwood and softwood, including stringy species, making it popular in cedar mills. To process logs end to end, a unique infeed rollcase allows the operator to load a log onto the infeed table while another is being debarked. This Debarker is built with hourglass rollcase-type infeed and outfeed conveyors. All functions are controlled from the operator's cab. The machine's hydraulic system is sufficient to power most infeed decks and debarker waste conveyors. This unit is generally used in barn pole, fence post and log home industries.

CAPACITY (DIAMETER RANGE) - 4" - 24", 10.2 cm - 61 cm

CAPACITY (LENGTH) - 8' - 70', 2.4 m - 21.3 m

POWER - 75 hp or 100 hp electric (diesel available), 55.9 kW or 74.6 kW

PRODUCTION RATE - 30 FPM (peeling), 9.1 m/min

INFEED/OUTFEED - 8' - 70' lengths, 2.4 m - 21.3 m

DEBARKER - Patented Morbark system floating cutterhead

OTHER FEATURES -

Hourglass rollcase type infeed and outfeed conveyors

8' to 20' (2.4 m - 6.1 m) infeed and outfeed sections complete with steel support legs and kicker assemblies

Outfeed conveyor has (1) set of hydraulic two-way kickers

Self-contained hydraulic system complete with operator’s controls

Hydraulic table lock assembly, vairable speed drive and infeed shoe

Adjustable infeed post

Legs are 34" (86.4 cm) to the top of infeed rolls

Motor base (frame size must be a minimum of 75 hp/55.9 kW) and V-belt drive

3-pump hydraulic system. All machine functions are completely hydraulically controlled with a variable speed on the feed wheels

Catalogs

C Series Debarker

1 Pages

Related Searches

- Mulcher

- Wood chipper

- Mobile wood chipper

- Log grapple

- Forestry harvester

- Forestry mulcher

- Mini skid steer loader

- Trailer-mount wood chipper

- Stump grinder

- Stationary wood chipper

- Debarker

- Diesel engine mini skid steer loader

- Crawler wood chipper

- Self-propelled stump grinder

- Crawler mini skid steer loader

- Crawler stump grinder

- Rotary-knife debarker

- Drum debarker

- Rosser head debarker

- Impeller debarker

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.