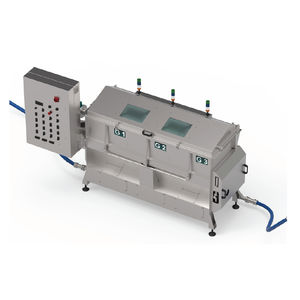

Olive oil production line TECNOTEMautomaticcontinuous

Add to favorites

Compare this product

Characteristics

- Type

- olive

- Other characteristics

- automatic, continuous

- Capacity

Min.: 500 kg

(1,102 lb)Max.: 4,000 kg

(8,818 lb)

Description

TECNOTEM plants have been designed for third-party processing or continuous or non-continuous customised company processing. How oxygen is managed at the infeed of the crusher characterises processing and represents a very important factor that allows the formation of Lipoxygenase and therefore Flavours. Equally important for the final quality of the product is the temperature delta of the paste between entering and exiting the crusher.

Malaxing is in a closed malaxer to prevent the paste from oxidising and control the temperature efficiently. Paste delivery is controlled by a solenoid valve and it is discharged by a Model PSS elliptical piston pump installed on each single malaxer. Cleaning is facilitated by the top cover that fully opens, so that there are no points where processing residues can remain.

The horizontal decanter that separates liquid from solid was developed to obtain the maximum output at the maximum quality; auger 2.0 was built to obtain a product that is always clean without adding water; there is no temperature increase during extraction.

VIDEO

Catalogs

Related Searches

- Filter with cartridge

- Food washing tunnel

- Fine filtration filter

- Separator filter for the food industry

- Vegetable food cleaning machine

- Mori-Tem plate filter

- Centrifugal separator filter

- Horizontal filter

- Wine filter

- Bypass filter

- Mori-Tem oil production line

- Mori-Tem olive oil production line

- Mori-Tem automatic oil production line

- Olive washing machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.