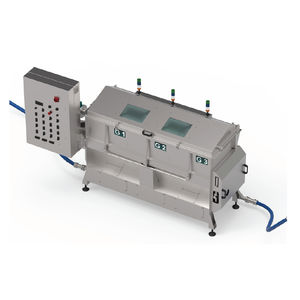

Olive oil production line SINTESI 150continuous

Add to favorites

Compare this product

Characteristics

- Type

- olive

- Other characteristics

- continuous

Description

The SINTESI 150 olive oil plant is composed of the FR_250_3 knives crusher unit with a mechanical speed change gear on the olives feeding auger, 250 mm diameter grid with cleaner, GV_150 vertical malaxer and electric panel with temperature controller and printer. The vertical malaxer works continuously and is equipped with a vacuum pump for mixing with a low pressure with inlet from the top and exit at the bottom through a PSS.1 transfer pump. The electrical panel is mounted on the crushing-mixing unit and is equipped with an inverter to change the speed of the crusher and the speed of the paste- lling pump. The TL_200 horizontal decanter can be mounted close on the same monoblock on wheels, or separate with anti-vibration feet; it has been developed to achieve maximum performance with the highest quality; the 2.0 auger was designed for getting a cleaner product without the addition of water; there is no temperature increase in extraction. It also features the PSS.1waste discharge pump on the decanter. In conclusion we can a rm that the SINTESI systems allow to extract a great product, taking advantage of the support that only our company can provide during all the processing phases: this makes the di erence. It is advisable to combine the Sintesi 150 with the DLE Mini leaf remover and the CPF.1 oil collecting vat with a 20×20 plate lter.

Standard voltage: 7.5 Kw three-phase 380V 50Hz (5-poles 32A SOCKET)

Catalogs

No catalogs are available for this product.

See all of Mori-Tem‘s catalogsRelated Searches

- Filter with cartridge

- Food washing tunnel

- Fine filtration filter

- Separator filter for the food industry

- Vegetable food cleaning machine

- Mori-Tem plate filter

- Centrifugal separator filter

- Horizontal filter

- Wine filter

- Bypass filter

- Mori-Tem oil production line

- Mori-Tem olive oil production line

- Mori-Tem automatic oil production line

- Olive washing machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.