Olive oil production line automaticcontinuousdiscontinuous

Add to favorites

Compare this product

Characteristics

- Type

- olive

- Other characteristics

- automatic, continuous, discontinuous

Description

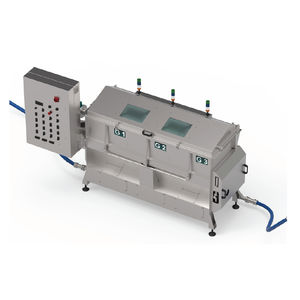

SINTESI equipment is designed for production of oil with high

phenolic level in small and medium-sized farms. Working process

can be continuous or discontinuous. The crusher is separated

and provided with an inverter for crushing turns regulation. The

handling of oxygen at the crusher inlet is a very important factor

allowing the formation of lipoxygenase, thus of .avours; also

important for the .nal product quality is the thermic delta between

the paste temperature when entering and when coming out of the

crusher. Malaxation is made inside closed, vertical malaxers, which

are designed to obtain light vacuum; temperature control is global.

Paste inlet is made through a pump operated by an electric valve

and the outlet by a PSS elliptical piston pump put on each single

malaxer. Cleaning is facilitated through the total opening of the

higher lid, so that there are no areas for possible process wastes.

Automatic washing is optionally available. The horizontal decanter

separating liquid from solid is designed in such a way as to obtain the

maximum yield with the highest quality; the 2.0 auger is designed

to get a cleanest possible product without adding any water; there

is no temperature increase during extraction. In conclusion we can

state that the SINTESI equipment allows extraction of a good quality

product, of course with all the support that can be granted by our

company during all phases of production: that makes the di.erence.

Catalogs

No catalogs are available for this product.

See all of Mori-Tem‘s catalogsRelated Searches

- Filter with cartridge

- Food washing tunnel

- Fine filtration filter

- Separator filter for the food industry

- Vegetable food cleaning machine

- Mori-Tem plate filter

- Centrifugal separator filter

- Horizontal filter

- Wine filter

- Bypass filter

- Mori-Tem oil production line

- Mori-Tem olive oil production line

- Mori-Tem automatic oil production line

- Olive washing machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.