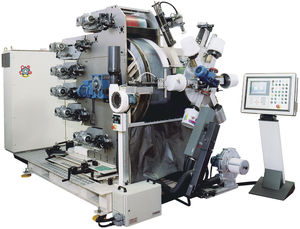

Dry offset press MO 2610for plastics

Add to favorites

Compare this product

Characteristics

- Heating technology

- dry

- Other caracteristics

- for plastics

Description

Automatic machine for the dry-offset printing up to 5 colours of aluminum or plastic closures. Available with 10 or 16 stations according to the characteristics of the line.

hinged roller-holding heads for easy opening in order to facilitate plate changing and plate and roller cleaning;

fine registers for the axial and peripheral adjustment of the plates. This operation can be carried out while the machine is working;

roller on ink fountain controlled by a 3-phase A.C. motor with frequency converter and electro-magnetic clutch in order to ensure the adjustment of a precise quantity of ink;

all the gears have inclined teeth to ensure a positive control and avoid shadows on the decoration;

electro pneumatic device for printing head shifting to prevent printing on the mandrel when a closure does not come into printing position (no container no printing device). Another device is activated together with no container no printing device, this device is called no container no inking and it disconnects all form rollers from their plates in order to avoid an excess of ink on the closure printed just after an empty mandrel;

lacquering unit;

Catalogs

No catalogs are available for this product.

See all of MOSS‘s catalogsRelated Searches

- Marking machine

- Stencil printer

- Automated marking machine

- Automatic stencil printer

- Color screen printing machine

- Screen printer for the plastics industry

- Offset printing machine

- Electronic stencil printer

- Tube marking machine

- Monochrome screen printing machine

- Plastic bottle screen printing machine

- Hot marking machine

- Plastic cap screen printing machine

- Web-fed offset printing machine

- 3-color screen printer

- Dry offset press

- Plastic offset press

- 5-color screen printer

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.