- Packing - Handling - Logistics

- Conveying

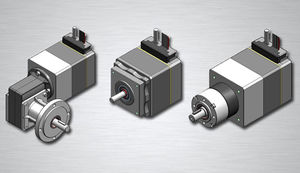

- Conveyor drum motor

- Motor Power Company

Conveyor motorized roller MTR

Add to favorites

Compare this product

Characteristics

- Options

- for conveyor

- Diameter

Max.: 76 mm

(3 in)Min.: 46 mm

(1.8 in)- Rated torque

Max.: 3.1 Nm

(2.3 ft.lb)Min.: 0.2 Nm

(0.1 ft.lb)

Description

A perfect combination of gearless motors and smart drives, these bundles were conceived as a specific product for conveyors, cross belts or any other roller transfer system. These controlled motion solutions ensure high durability since they can withstand the wear and tear of frequent use in a demanding environment and the units are able to handle an extensive range of tasks and materials, in order to be useful in several handling applications.

Available in two versions: the frameless cartridge motor without tube, for insertion into the roller; and power pack version, a ready-to-use motorized unit that includes cartridge and rollers in different design. The motor uses technology derived from direct drive torque motors. Consequently, the motion is transmitted directly from the motor to the load, with no gear transmission mechanisms involved.

Characteristics

Gearless is better why this technology ensures:

• High MTBF, since the motor-driven roller requires fewer components than a motor-gearbox pair

• Improved system efficiency, due to the absence of gears in the motor

• Accuracy, thanks to feedback reliability

• High dynamics with direct drive technology

• Smoother and quieter operation, due to the absence of gears in the motor

• Easy replacement: with DMR Drive’s auto-addressing system, no configuration is required when replacing with a new motor driven roller

• Easy commissioning; a unique part number does away with the need to handle different gearbox ratios according to different speed needs

• Wide choice of speeds: only one motor driven roller for the entire speed range

Catalogs

No catalogs are available for this product.

See all of Motor Power Company‘s catalogsRelated Searches

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.