Gas filter cartridge oilwaterfor chemical products

Add to favorites

Compare this product

Characteristics

- Media

- water, oil, for chemical products, for gas

- Type of filtration

- fine

- Material

- fluoropolymer

- Applications

- for general purposes, industrial, for chemical applications, for biodiesel

- Domain

- industrial

Description

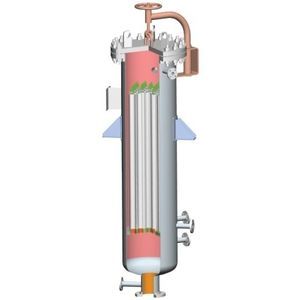

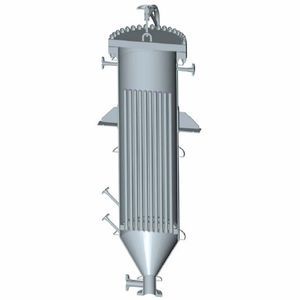

At Mott, we offer a full range of liquid-liquid coalescer and gas-liquid coalescer systems for use in various industrial applications to remove particulate matter, water, and other liquids. The CC Series Liquid-Liquid Coalescers are designed to separate two liquid phases with different characteristics of density, viscosity, and interfacial tension (IFT). They efficiently separate liquid-liquid emulsions in oil, gas, and chemical applications extending equipment life. The GLP Series Gas-Liquid Coalescers are designed to remove water, carried over amine aerosols, and fine particulate from process gas, fuel gas, natural gas, methane, hydrogen, and other technical gases. Liquid-liquid coalescers, gas-liquid coalescers, pre-filters, and full systems are available.

Liquid-liquid coalescers and gas-liquid coalescers are used in oil refineries to remove oil and water from hydrocarbon gases. In the refining process, they are placed between the atmospheric distillation column and the vacuum distillation column. Coalescers work by bringing oil and water droplets together, so they may be separated easily. A coalescer air filter is typically used in compressed air systems to remove oil and water vapor from the air. The coalescing filter – made up of a succession of filtering media that combine contaminants to make them easier to separate fluid mixtures – is used to remove contaminants before they can enter the system and cause damage.

Catalogs

No catalogs are available for this product.

See all of Mott‘s catalogsRelated Searches

- Liquid separator filter

- Filter cartridge

- Industrial filter cartridge

- Filter for industrial applications

- Stainless steel separator filter

- Fine filter cartridge

- Filtration system

- General purpose filter cartridge

- Water filter cartridge

- Polymer filter cartridge

- Liquid filtration system

- Gas pre-filter

- Process separator filter

- Chemical product filter cartridge

- High-efficiency pre-filter

- Oil separator filter

- High-performance pre-filter

- Flange-mount filter

- Separation filter

- Separator filter for the food industry

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.