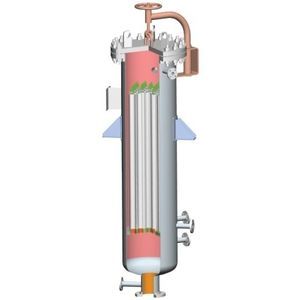

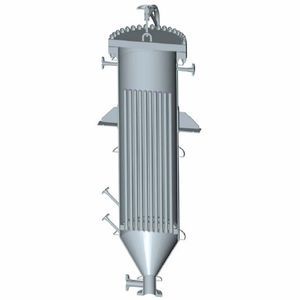

Liquid filter for solidsfor chemical applicationsprocess

Add to favorites

Compare this product

Characteristics

- Designed for

- liquid, for solids

- Applications

- process, for chemical applications, separation

- Material

- stainless steel

- Cleaning

- backwash

- Fluid specification

- for corrosive liquids

- Other characteristics

- high-temperature, tangential

Description

Bioprocessing scale-up and production is rapidly evolving in an ongoing effort to improve product yield, consistency, and quality. Innovations in new expression systems bring new challenges in process aeration and filtration. Mott’s bioprocessing filters are specifically designed for high-cell-density broth filtration, improves yields and accelerates filtration efforts, addressing critical challenges in bioprocessing. Our bioprocessing filter solutions are tailored to meet the unique requirements of each bioprocessing application, ensuring optimal performance in separating cells and other particulates from the culture medium. Talk to one of our application engineers to learn more about how Mott filtration systems, including our advanced bioprocessing filter options, can solve your challenges in bioprocessing and enhance your production efficiency.

Typical Applications

Tangential Flow Filtration

Cell Retention Systems

Cell & Debris Separation

Cell Harvest

Clarification

Vessel Diameter -

Common Diameters – 4” to 72” diameter vessels are common to accommodate a wide range of flow rates.

Custom vessels are available upon request, consult factory

Filtration Efficiency -

Media grade elements down to 0.2 um are available to capture even the smallest particles in your process for a purer end product.

Material Choices -

Common filter element alloys – 316L SS, 310 SS, Hastelloy C-276, Hastelloy X, Monel 400, Nickel 200, Inconel 600

Common vessel alloys – 316L SS, Inconel, Hastelloy

Other alloys are available, consult factory

Operating Temperatures -

Alloys with temperature resistance up to 1400 degrees Fahrenheit are available.

Catalogs

No catalogs are available for this product.

See all of Mott‘s catalogsRelated Searches

- Liquid separator filter

- Filter cartridge

- Industrial filter cartridge

- Filter for industrial applications

- Stainless steel separator filter

- Fine filter cartridge

- Filtration system

- General purpose filter cartridge

- Water filter cartridge

- Polymer filter cartridge

- Liquid filtration system

- Gas pre-filter

- Process separator filter

- Chemical product filter cartridge

- High-efficiency pre-filter

- Oil separator filter

- High-performance pre-filter

- Flange-mount filter

- Separation filter

- Separator filter for the food industry

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.