Fuel filter oilfor solidsfor storage tanks

Add to favorites

Compare this product

Characteristics

- Designed for

- oil, fuel, for solids

- Applications

- for storage tanks

- Cleaning

- backwash

- Filtration size

Max.: 54 µm

Min.: 24 µm

- Fluid temperature

Max.: 330 °C

(626 °F)Min.: 150 °C

(302 °F)

Description

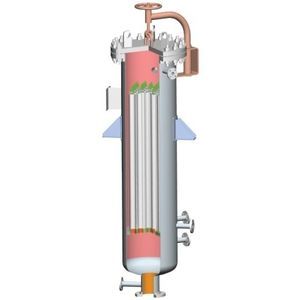

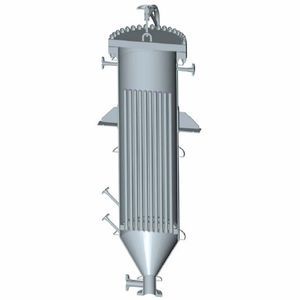

Mott’s FCC/RFCC slurry oil filters excel at removing alumina-silica and other solids contaminants from main column bottom slurry feeds. With online clean-in-place automated backwashing, our slurry oil filters achieve filtrate quality below 100 ppm total suspended solids. This ensures the filtered oil can be used for blending or sold as valuable product into other applications. Backwashed slurry can be recycled back to the riser, decanted and concentrated, or sent directly to disposal or reprocessing. Mott’s install base includes 20+ filters on five continents in both FCC and RFCC applications.

Typical Applications

FCC/FCCU Main Column Bottom Slurry Filter

RFCC Main Column Bottom Slurry Filter

Hydrotreater Slurry Filter

Vessel Diameter -

Standard Diameters – 24” to 66” diameter vessels are standard to accommodate a large range of flow rates and production volumes, ranging from 1,000 barrels per day to 20,000 barrels per day

Solid Weight % -

Weight percentages between 0.1-1% are standard, but designs can be modified to accommodate unique feed streams

Standard Materials -

Standard filter element alloys – 316L SS

Standard vessel alloys – 316L SS

Other alloys are available, consult factory

Operating Temperatures -

Up to 800 degrees Fahrenheit

Custom alloys available to accommodate unique operating temperatures, consult factory

Cleaning -

LSI filters for FCC/RFCC are designed for clean-in-place performance. This means filter elements can discharge cake build-up without having to open the filter for maintenance. Once terminal pressure drop has been reached, the cleaning cycle automatically initiates.

Catalogs

No catalogs are available for this product.

See all of Mott‘s catalogsRelated Searches

- Liquid separator filter

- Filter cartridge

- Industrial filter cartridge

- Filter for industrial applications

- Stainless steel separator filter

- Fine filter cartridge

- Filtration system

- General purpose filter cartridge

- Water filter cartridge

- Polymer filter cartridge

- Liquid filtration system

- Gas pre-filter

- Process separator filter

- Chemical product filter cartridge

- High-efficiency pre-filter

- Oil separator filter

- High-performance pre-filter

- Flange-mount filter

- Separation filter

- Separator filter for the food industry

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.