Liquid filter stainless steelbackwash

Add to favorites

Compare this product

Characteristics

- Designed for

- liquid

- Material

- stainless steel

- Cleaning

- backwash

Description

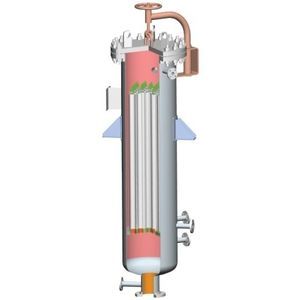

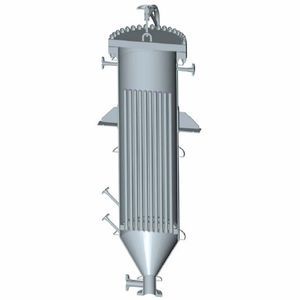

Mott, a trusted name in filtration, has been at the forefront of purifying both crude terephthalic acid (CTA) and purified terephthalic acid (PTA) for decades, employing cutting-edge HyPulse® LSI and LSM technologies. Mott’s liquid filters, equipped with advanced terephthalic acid filters, can be easily tailored to accommodate multiple wash and purge steps crucial in the CTA and PTA processes, ensuring impeccable product quality. These innovative terephthalic acid filters from Mott not only reduce caustic acid consumption within the CRU but also minimize organic loads in wastewater treatment, while recovering up to 2 wt.% solids from CTA or PTA applications.

In scenarios where corrosion control is paramount, the Mott LSI serves as an intermediate filter, efficiently removing precipitated corrosion metals before downstream processing. The remarkable return on investment (ROI) for a Mott LSI in a CTA or PTA application averages just two years, making it a sound choice for those seeking enhanced efficiency and cost savings with top-notch terephthalic acid filters.

Typical Applications

CTA Mother Liquor Recovery

CRU Corrosion Metal Removal

CTA Residue Stream Catalyst Recovery

PTA Mother Liquor Recovery

PTA Makeup Catalyst Recovery

Vessel Diameter -

Standard Diameters – 4” to 72” diameter vessels are standard to accommodate a wide range of flow rates.

Custom vessels are available upon request, consult factory

Filtration Efficiency -

Various media grade elements are available to capture solids at greater than 99% removal efficiency, depending on the particle size distribution of the solids

Catalogs

No catalogs are available for this product.

See all of Mott‘s catalogsRelated Searches

- Liquid separator filter

- Filter cartridge

- Industrial filter cartridge

- Filter for industrial applications

- Stainless steel separator filter

- Fine filter cartridge

- Filtration system

- General purpose filter cartridge

- Water filter cartridge

- Polymer filter cartridge

- Liquid filtration system

- Gas pre-filter

- Process separator filter

- Chemical product filter cartridge

- High-efficiency pre-filter

- Oil separator filter

- High-performance pre-filter

- Flange-mount filter

- Separation filter

- Separator filter for the food industry

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.