Solid filter processstainless steelbackwash

Add to favorites

Compare this product

Characteristics

- Designed for

- for solids

- Applications

- process

- Material

- stainless steel

- Cleaning

- backwash

- Fluid specification

- for corrosive liquids

- Other characteristics

- high-temperature

Description

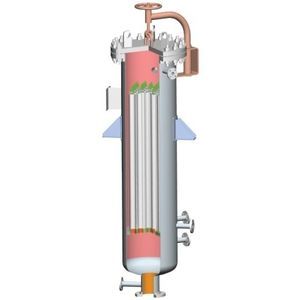

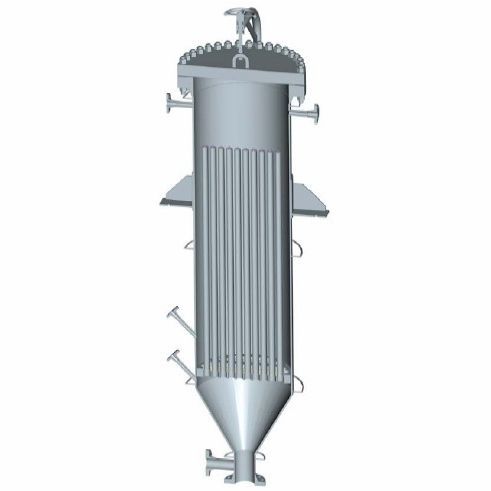

LSI filters incorporate proprietary inside-out filtration technology, making them ideal as corrosive-resistant process filters. After each cycle, solids are backwashed off the inside of the elements and discharged as a concentrated slurry or wet cake. LSX filters provide uninterrupted filter cycle performance through cross-flow filtration, suited for corrosive-resistant applications. Slurries flow through the filter elements, allowing filtrate to exit the system on a continuous basis while particulates remain in the recirculating stream. LSP filters offer conventional outside-in filtration for polishing streams with solids concentrations of less than 100 ppm, designed for use in corrosive environments. LSM filters place inside-out filtration within a double open-ended design which is ideal for high-density solids or solids concentration, providing a solution for corrosive-resistant process filtering needs.

Typical Applications

Valuable catalyst recovery, such as carbon-based precious metal, slurry oil, activated carbon, organic salts, Raney nickel, copper chromite, and other catalyst recovery applications.

High temperature, corrosive liquid filter applications

Reducing worker exposure to hazardous chemicals

Continuous loop reactors

Concentration of radwaste

Ion exchange filtration

Continuous filter processes

Catalogs

No catalogs are available for this product.

See all of Mott‘s catalogsRelated Searches

- Liquid separator filter

- Filter cartridge

- Industrial filter cartridge

- Filter for industrial applications

- Stainless steel separator filter

- Fine filter cartridge

- Filtration system

- General purpose filter cartridge

- Water filter cartridge

- Polymer filter cartridge

- Liquid filtration system

- Gas pre-filter

- Process separator filter

- Chemical product filter cartridge

- High-efficiency pre-filter

- Oil separator filter

- High-performance pre-filter

- Flange-mount filter

- Separation filter

- Separator filter for the food industry

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.