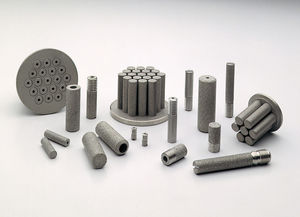

Nickel filter stainless steel

Add to favorites

Compare this product

Characteristics

- Material

- stainless steel, nickel

- Operating pressure

Min.: -1 bar

(-14.504 psi)Max.: 689 bar

(9,993.1 psi)

Description

Mott has customized various propulsion filters and fluid management technologies for mission critical spacecraft applications through joint projects with partners in the space community. In addition, our experience with additive manufacturing propellant filter design allows quick prototype turnaround, flexibility for complex designs, and integration of porous and solid technology without welds. These lightweight solutions are available in materials like titanium and stainless steel to suit various fluids and application needs.

Our scalable, customizable filtration solutions are crafted by a skilled team using precise manufacturing processes, ensuring propellant and space propulsion filters meet your exact specifications.

Typical Applications

Satellite Propellant thruster inlet filter

Hydrazine feed system filters

Injector diffuser screens

Catalyst bed retainer screens

Environmental and life support systems

Helium actuation

Product Specs

Materials of Construction -

Titanium 6AI4V (Gr.5)

316L Stainless Steel

Nickel

Standard Testing Performed -

Filtration Efficiency

Proof

Bubble Point

Mass

Flow vs Pressure Drop

Helium Leak

Application Sizes -

Micro satellites: less than 10 kg

Small satellites: 10 to 100 kg

Medium satellites: 500 to 1000 kg

Large satellites: great than 1000 kg

Specifications -

Operating Pressures: - -14.7 to 10,000 psig (-1 to 689 barg)

Operating Temp: - -100° to 700°F (-73° to 371°C)

Particle Removal: - MIL-STD-1246 (10-25µ ABS Filtration)

Leak Testing: - ≤ 1.0E-6 sccs GHe

Environmental Testing: - Goddard Standard GSFC-STD-7000

Flow vs Pressure Drop: - 0.5 lb/s to 7 lb/s at <15 psid

Wetted Cleanliness: - Per IEST-STD-CC1246E

Catalogs

No catalogs are available for this product.

See all of Mott‘s catalogsRelated Searches

- Liquid separator filter

- Filter cartridge

- Industrial filter cartridge

- Filter for industrial applications

- Stainless steel separator filter

- Fine filter cartridge

- Filtration system

- General purpose filter cartridge

- Water filter cartridge

- Polymer filter cartridge

- Liquid filtration system

- Gas pre-filter

- Process separator filter

- Chemical product filter cartridge

- High-efficiency pre-filter

- Oil separator filter

- High-performance pre-filter

- Flange-mount filter

- Separation filter

- Separator filter for the food industry

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.