Optimize the profitability of your systems. The DP4 dosing quantity test system (flow sensor) enables you to effortlessly determine the right dosing quantity. Even bubbles can now be identified through measuring. The DP4 is a must if it comes to Industry 4.0, in order to be able to guarantee complete monitoring of the processes and to identify trends.

Software

- Integration of the controller (blue) via Profinet and series connection of further DP4 possible

- Parameterization via any browser using the http protocol

- Or parameterization via PLC, Beckhoff, and other systems

- No additional software or app needed

Installation

- Easy integration upstream of the dosing valve

- Space-saving assembly of several DP4s in a row

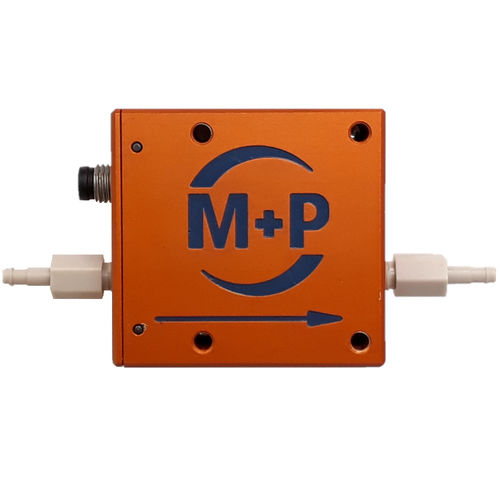

- Very small dimensions of the sensor (orange)

- Screw points on each side sensor surface

Quality assurance / monitoring

- Identification and definition of ideal quantity

- Detection of bubbles in the medium

- Creation of freely adjustable tolerance windows

- Monitoring of multiple cycles

- Identification of trends and errors using the ‘Industry 4.0’ standard

Measurable dosing quantities: 0.005 … 5 ml/min

- Switching limits: continuous or by tact

- Cycle time: max. 40 ms

- Operating pressure: < 15 bar

- Operating voltage: 24 Volt

- Interface: Profinet

- Working principle: thermal

- Design: separate sensor and controller

- Commissioning: via PLC (PN) or browser (http)

- Degree of protection: IP64 (controller) – IP67 (sensor)

DOSING QUANTITY TEST SYSTEM