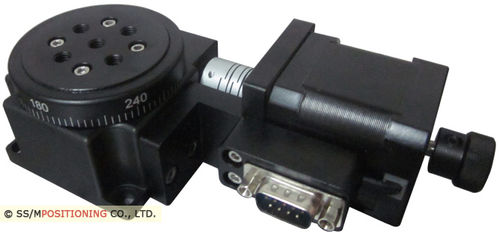

Rotary stage MR60motorized1-axisminiature

Add to favorites

Compare this product

Characteristics

- Orientation

- rotary

- Type

- motorized

- Number of axes

- 1-axis

- Other characteristics

- miniature, high-accuracy

Description

Details :

Miniature Motorized Rotation Stage

1. Key Features

- Continuous 360° Rotation

- 1° Graduations on Main Dial

- 60 mm in Diameter of Platform Size

- Preloaded Worm Gear Drive Mechanism with Low Backlash

- Optional function: Rotary Encoder, Servo Motor

The Motorized Rotation Stage is a high-precision positioning productions designed and built in a various of positioning solutions to research and academia, photonics and optics, testing and measurement, life science and material science and industry markets. Applications of Rotation Stages include semiconductor wafer inspection or scribing, optics positioning, metrology, etc.

The MR60 Rotation Stage provides arcsecond resolution when driven from a microstepping setting in stepper motor control. The main body of the stage is made from alluminum alloy and can attach directly to an optical table. A worm gear drive mechanism with 90:1 dear ratio is used to transfer the rotary motion of the stepper motor into rotary motion of the carriage.

The stepper motor used in 2 phases and 1.8° of step angle is ideally suited for microstepping applications that require the high resolution.

Catalogs

No catalogs are available for this product.

See all of MPositioning Co., Ltd.‘s catalogsOther MPositioning Co., Ltd. products

Motorized positioning stages

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.