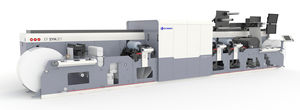

In-line flexographic press EXL8-colorlabelHot air drying

Add to favorites

Compare this product

Characteristics

- Type

- in-line

- Number of colors

- 8-color

- Application

- label

- Other characteristics

- Hot air drying, for packaging, UV drying

Description

The MPS EXL-Packaging press delivers wider and faster flexo printing without limits. Flexible packaging printing and converting with the use of an inline press is more economical then ever. With the EXL-Packaging press, extremely fast change-over times and remarkably short set-up waste guarantee optimal and productive printing and converting.

The EXL Packaging press can be equipped with UV, hot-air and LED drying technology, allowing users to print on a very large variety of substrates including thin film, paper, cartonboard, shrink sleeves, inmould, lamitube and flexible packaging.

In order to drive down the cost per 1,000 labels, MPS introduced Automated Print Control (APC) which provides automated servo control of all relevant press settings. Thanks to APC, press settings and controls are extremely easy to operate and replicate through job memory, resulting in virtually no set-up waste for repeat jobs.

Catalogs

Brochure 2017

15 Pages

Related Searches

- Flexographic press

- Offset printing machine

- In-line flexographic press

- Paper flexographic press

- 8-color flexographic press

- Packaging flexographic press

- Medium-sized offset press

- Label flexographic press

- Web-fed offset printing machine

- 3-color flexographic press

- 8-color offset press

- Inkjet flexographic press

- Wet offset press

- UV drying flexographic press

- Offset press with thermal drying

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.