- Industrial machines and equipment

- Welding and Assembly

- Ultrasonic welding machine

- MS Ultraschall Technologie GmbH

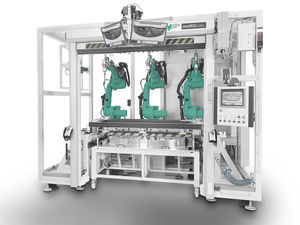

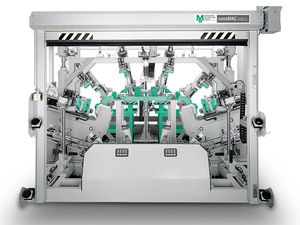

Ultrasonic welding machine MS sonxMAC MULTIroboticstandalonefor plastics

Add to favorites

Compare this product

Characteristics

- Technique

- ultrasonic

- Operational mode

- robotic

- Configuration

- standalone

- Applications

- for plastics

- Other characteristics

- high-precision, sliding table

Description

Our individual machine concept MS sonxMAC MULTI is designed for multiple processing steps in a single part handling and can be easily and reliably combined with additional processes.

Several processing positions and process steps in a single machine

Short sequence times and optimized process flow due to parallel loading and machining sequence

Precise positioning and adherence to tolerances due to workpiece clamping

Reproducibility and quality monitoring via process documentation

Optimized solution for series production of complex components

Several processing steps in a single part handling

Optimal cycle time: loading and unloading parallel to the welding process

High productivity through shorter cycle times

Low-maintenance drives with electronic control

Turntable machine

Shuttle sliding table machine

Sliding table machine

Moving top platen machine

Combined sliding table and moving top platen machine

Catalogs

No catalogs are available for this product.

See all of MS Ultraschall Technologie GmbH‘s catalogsOther MS Ultraschall Technologie GmbH products

MS sonxMAC ULTRASONIC CUSTOM WELDING MACHINES

Related Searches

- Welding system

- Automatic welding system

- Manual gun

- Precision welding system

- Plastic welding system

- Resistance welding system

- Standalone welding system

- Compact welding system

- Pneumatic welding system

- Ultrasonic welding system

- Integrated welding system

- Electric welding system

- Benchtop welding system

- Welding gun

- High-precision welding system

- 380V three-phase welding system

- Custom welding system

- Cost-effective welding system

- Rotary welding system

- Robotic welding system

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.