- Industrial machines and equipment

- Welding and Assembly

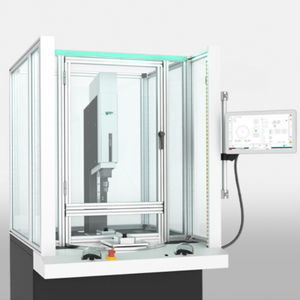

- Ultrasonic welding machine

- MS Ultraschall Technologie GmbH

Ultrasonic welding machine MS sonxTOP MULTIautomaticbenchtoponline

Add to favorites

Compare this product

Characteristics

- Technique

- ultrasonic

- Operational mode

- automatic

- Configuration

- benchtop, online

- Applications

- for plastics

- Power supply

- 380V three-phase

- Other characteristics

- high-precision, custom

- Output frequency

Max.: 40 kHz

Min.: 20 kHz

Description

We are pleased to present the new MS sonxTOP MULTI. With features of the innovative, high-precision production MS sonxTOP machines and the proven, reliable custom machines MS sonxMAC, you are sure to have the best of both worlds.

The standardized machine concept enables you to develop more complex and larger components via a modular workroom design to manufacture it. Challenging applications can be precisely implemented here. A profitable and sustainable investment with high efficiency potential.

Individual design of the workroom with proven ultrasonic welding units in the frequency classes from

Highest strength values for the welding result thanks to a precise servo drive

Standardized, intuitive control technology with the MS Sequence function makes it possible to perform a machine function in the shortest time and without programming knowledge via the HMI

Through standardization, we guarantee you significantly shorter delivery times up to 50% (12–16 weeks)

Cost-attractive alternative to our proven custom machines

Increased longevity due to end-to-end standardization

The workroom of up to W x D: 600 x 300 mm offers you a lot of space to process your products

Unbeatable energy efficiency thanks to integrated servo drive technology

You invest in intelligent and seamless connectivity for your industry 4.0 production

Small to medium-sized components with e.g. round and longitudinal ridoms, surface welding, spot welding. Examples include:

A/B/C column fairings passenger cars

Interior decor elements cars

Loudspeaker cars

Welding of electronic components

Catalogs

MS sonxTOP MULTI

2 Pages

Other MS Ultraschall Technologie GmbH products

MS sonxTOP ultrasonic plastic welding machines

Related Searches

- Welding system

- Automatic welding system

- Manual gun

- Precision welding system

- Plastic welding system

- Resistance welding system

- Standalone welding system

- Compact welding system

- Pneumatic welding system

- Ultrasonic welding system

- Integrated welding system

- Electric welding system

- Benchtop welding system

- Welding gun

- High-precision welding system

- 380V three-phase welding system

- Custom welding system

- Cost-effective welding system

- Rotary welding system

- Robotic welding system

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.