- Industrial machines and equipment

- Welding and Assembly

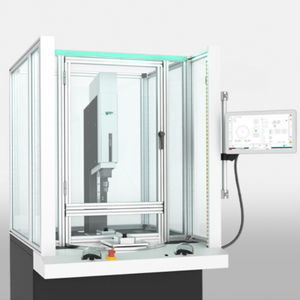

- Ultrasonic welding machine

- MS Ultraschall Technologie GmbH

Ultrasonic welding machine MS sonxTOP MEMBRANEautomaticfor integrationfor plastics

Add to favorites

Compare this product

Characteristics

- Technique

- ultrasonic

- Operational mode

- automatic

- Configuration

- for integration

- Applications

- for plastics

- Power supply

- 380V three-phase

- Other characteristics

- high-precision, integrated

Description

To save material and production costs of plastic parts with integrated membranes: MS sonxTOP MEMBRANE. Whether as a manual workstation or integrated in an automation system, the modular solutions integrates punching and sealing of the membrane in one process step (among others DAE [pressure equalization elements]) in a cycle time of less than 2 seconds. In short, the ultrasonic machine combines four process steps. Strip transport with splice control, mechanical punching out of the strip material, transport of the membrane die-cuts to the sealing position and lastly, sealing of the die-cuts by means of ultrasonic on the plastic components.

To reduce machine downtime to a minimum, when changing the punching and sealing tools, the MS sonxTOP MEMBRANE has an innovative quick tool change system which enables tools to be changed in under five minutes (without the cutting gap between the sonotrode and the punching die needing to be adjusted).

Available as a manual workstation (table machine) and for integration into automation systems as a stand and inline module

Punching and welding in one work step

Material savings due to individually adjustable cycle widths

Integrated leak test (optional)

Integrated belt monitoring (optional)

Splice point control (optional)

Job change possible, in just a few minutes, due to preset punch-seal tools

Unbeatable energy efficiency and high positioning accuracy thanks to integrated servo drive technology

You are investing in intelligent and seamless connectivity for your Industry 4.0 production

Catalogs

MS sonxTOP MEMBRANE

2 Pages

Other MS Ultraschall Technologie GmbH products

MS sonxTOP ultrasonic plastic welding machines

Related Searches

- Welding system

- Automatic welding system

- Manual gun

- Precision welding system

- Plastic welding system

- Resistance welding system

- Standalone welding system

- Compact welding system

- Pneumatic welding system

- Ultrasonic welding system

- Integrated welding system

- Electric welding system

- Benchtop welding system

- Welding gun

- High-precision welding system

- 380V three-phase welding system

- Custom welding system

- Cost-effective welding system

- Rotary welding system

- Robotic welding system

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.