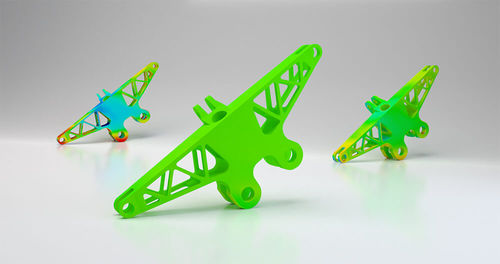

Simulation software for process design, virtual testing and optimisation of metal-based additive manufacturing

To prevent costly defects, Simufact Additive enables the easy-to-use virtual simulation of the entire production process: From Support structure generation and removal to heat treatment, machining and more.

Simufact Additive is a scalable software solution for the simulation of metal-based additive manufacturing processes which focuses on laser powder bed fusion (L- PBF) and metal binder jetting (MBJ) processes.

Simufact Additive is a software solution designed to predict and compensate for distortion, residual stress and temperature distribution throughout the printing, heat treatment, cutting, hot isostatic pressing (HIP) as well as machining processes virtually before the part is manufactured by the 3D metal printer in reality.

Metal Powder Bed Fusion (PBF) is an advanced additive manufacturing technique that creates complex metal parts by selectively fusing layers of metal powder using a high-energy laser.

The process involves depositing a thin layer of metal powder and then using the energy source to melt and solidify the powder. As each layer fuses, a three-dimensional object is built up step by step with precise geometry and intricate internal structures.

Simufact Additive can simulate the entire process and prevent costly issues during manufacturing.