Dytran delivers a structural, material flow and coupled FSI analysis capabilities in a single package.

Perform explicit Transient Dynamic Solution for Crash, Impact and Fluid-Structure Interaction Studies for improved product safety and reduced warranty costs.

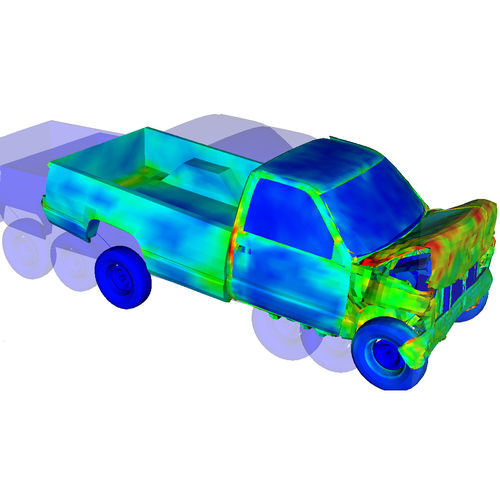

Dytran is an explicit finite element analysis (FEA) solution for simulating short-duration events like impact and crash, and to analyze the complex nonlinear behavior that structures undergo during these events. Dytran enables you to study the structural integrity of designs to ensure that final products stand a better chance of meeting customer safety, reliability, and regulatory requirements.

Dytran delivers a structural, material flow and coupled FSI analysis capabilities in a single package. Dytran uses a unique coupling feature that enables integrated analysis of structural components with fluids and highly deformed materials in one continuous simulation.

Dytran’s accuracy has been proven through correlation with physical experiments. Dytran helps engineers predict how a prototype would respond to a variety of real-world dynamic events and to examine potential causes for product failure. Some industry application examples include:

Aerospace Applications: Aircraft ditching, fuel tank sloshing and rupture, bird strike simulation, engine blade containment, aircraft crashworthiness, seat design and safety, aircraft and cargo containment hardening

Automotive Applications: Airbag design and occupant safety (out of position studies), dummy modeling and seat design, vehicle impact and crash testing, tire hydroplaning, fuel tank sloshing and rupture