Advanced simulation software orchestrates metal forming, unlocking the art of successful cold forming, hot forging, rolling, and stamping.

Simufact Forming is a simulation tool for the practitioner in forming technology. Our claim is to consistently align the software to the practical needs of the user.

Often, expert knowledge is required to operate simulation environments in order to build and program complex models. This is not the case with Simufact Forming. The user does not have to deal with the gray physics of the forming process nor with simulation specific details. Simufact Forming is practical and can be learned quickly and easily. The forming practitioner can thus concentrate on the details of his forming processes instead of on the software.

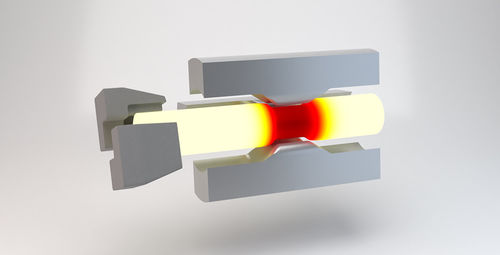

Forming processes conducted significantly below the recrystallisation temperature of the material. These processes include typical upsetting and extrusion processes (e. g. for the production of bolts, nuts and rivets), but can also include coining, cold hobbing, thread rolling and last but not least drawing processes (e. g. wire drawing, tube drawing and profile drawing).

Forming processes conducted above the recrystallisation temperature of the material. A typical process is hot forging, including closed die hot forging, auxiliary processes such as heating and cooling, cutting processes and preform operations (e. g. upsetting, bending, forge rolling and cross wedge rolling) as well as extrusion processes.