- Robotics - Automation - Industrial IT

- Industrial Software

- Control software

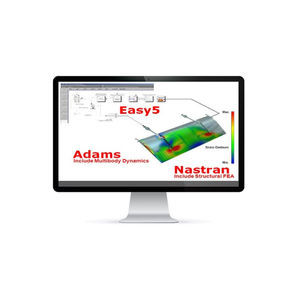

- MSC SOFTWARE - HEXAGON MANUFACTURING INTELLIGENCE

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

Quality software Simufact Weldingsimulationcontroldatabase

Add to favorites

Compare this product

Characteristics

- Function

- quality, simulation, control, database

- Applications

- process, for welding applications

Description

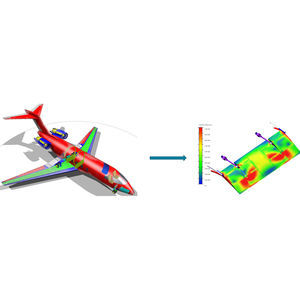

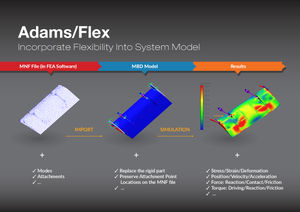

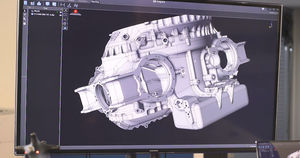

Robustly simulate complex multi-station fixturing and assembly of complex assemblies with hundreds of joints. Perform a “virtual tryout” before the first part is fabricated.

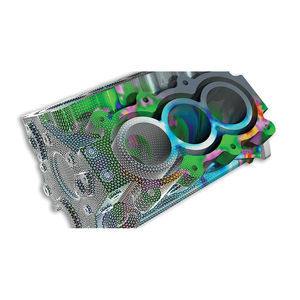

Simufact Welding is used to model and optimise a variety of thermal joining processes, taking into account the welding sequence and fixture.

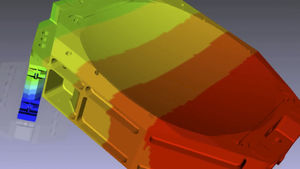

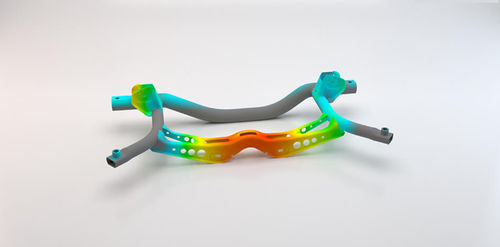

One of the biggest challenges in welding is the thermal deformations or residual stresses of the entire assembly that occur after a non-optimised welding and clamping process. As a result, subsequent assembly processes cannot be easily performed because the geometry of the sub-assembly is out of tolerance. With Simufact Welding, the welding process and parameters can be optimised to achieve the desired product quality.

With the Arc Welding module common arc welding processes are simulated. Residual Stress, strain and distortion as caused by the welding process are predicted. This enables an improved quality and dimensional control.

Simufact Welding allows to evaluate the impact of vaious parameters, like: weld sequence, arc welding process parameters and fixturing strategy.

Multiple weld robots can be configured. Weld fillets are modelled very easily using the internal fillet generator.

Simufact Weldiing makes use of a comprehensive material database that can be extended by the user

VIDEO

Catalogs

No catalogs are available for this product.

See all of MSC SOFTWARE - HEXAGON MANUFACTURING INTELLIGENCE‘s catalogsOther MSC SOFTWARE - HEXAGON MANUFACTURING INTELLIGENCE products

Products

Related Searches

- Automation software solution

- Management software solution

- Analysis software solution

- Process software solution

- Windows software solution

- Computer-aided design software

- Control software solution

- Real-time software solution

- Online software

- Design software solution

- 3D software solution

- Monitoring software solution

- Interface software

- Measurement software

- Industrial software solution

- Quality software

- Simulation software

- Visualization software solution

- Automated software

- Development software

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.