Chemical tempering is one of the methods used to increase the surface hardness of glass. In this method, it is ensured that the sodium atoms in the glass are replaced with potassium atoms in the region close to the surface. This creates tension on the surface of the glass. It gives strength and hardness to the glass.

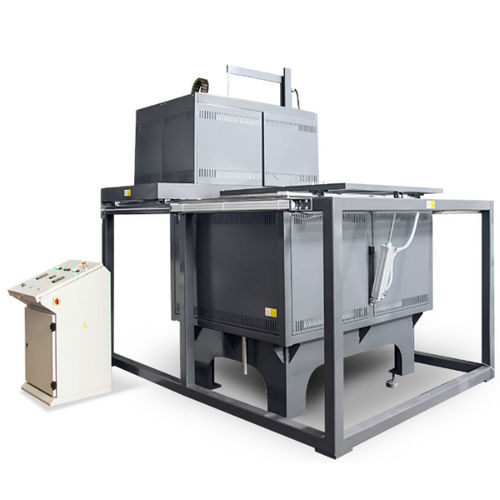

In the chemical glass tempering furnace is produced by our company, the glass is heated by a constant temperature increase, then it is immersed in the salt bath. After being kept in a salt bath for a sufficient time, it is cooled slowly. So that the glass is not broken by thermal shocks and hardness of the surface of the glass increases.

All this is done automatically with a pre-installed program at chemical glass tempering furnace. Chemical glass tempering furnace and glass holding baskets can be designed and produced by our company. This feature allows the use of tempered glass in various fields such as automotive, electronics, architectural, aeronautical, naval and military. This method is a unique method for increasing the strength of thin glasses. MSE is manufactured up to 900 °C chemical glass tempering furnace.

STANDARD FEATURES

Programmable step controller via digital display

Observation of set and real temperature

Delayed start and program save feature

Temperature control via PID and ±1°C temperature display sensitivity

System protection for over temperature,audio visual warning alarm

Error display in case a breakdown

Percentage of electrical energy consumption

Able to resume the program after the power failure

Electronic safety system, emergency stop button