Lathe steady rest

Add to favorites

Compare this product

Characteristics

- Application

- for lathes

Description

How to machine long parts on a slant bed turning center not prearranged for the use of a steady rest? We have the solution for you!

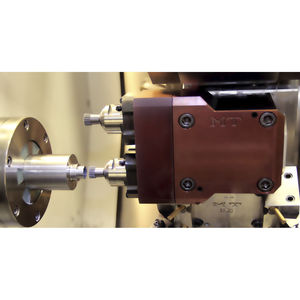

The sliding steady rest module (solution patented by M.T.) requires the driven tool power only to operate both the sliding to reach the piece, as well as the closing and opening of the hydraulic steady rest.

The structure is designed in order to reduce the problems of interference in the machining area also on small size machines and working on the sub spindle.

The sliding steady rest module can be equipped with wireless microswitches to detect the parking position and the position of piece support. M.T. can supply a dedicated control unit for the interface with the numeric control of the machine.

The tightening force can be easily adjusted by operating on the dedicated valves.

Product features

The main features of M.T.'s sliding steady rest module are:

- Allows the machining of long parts on lathes not prearranged for the assembly of an hydraulic steady rest!

- Does not require additional piping or complicated cables or rotary distributors on the turret!

- Cost effective compared to the mounting of an additional carriage for the steady rest!

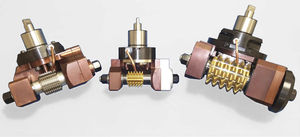

The sliding steady rest module is available in two different sizes:

- Size 1: for parts with diameter 4 - 64 mm

- Size 2: for parts with diameter 8 - 101 mm

The sliding steady rest module is necessary for many multi turret turning center and is available for many different machine models.

VIDEO

Catalogs

No catalogs are available for this product.

See all of MT‘s catalogsRelated Searches

- Chuck

- Machining tool holder

- Electrospindle

- Collet tool holder

- Motorized motor spindle

- Modular chuck

- Quick-change chuck

- Quick-change tool holder

- Weldon chuck

- Drilling motor spindle

- ER tool holder

- Modular tool holder

- Grinding motor spindle

- VDI chuck

- Weldon tool holder

- VDI tool holder

- High-speed motor spindle

- Static chuck

- BMT tool holder

- Static tool holder

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.