- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

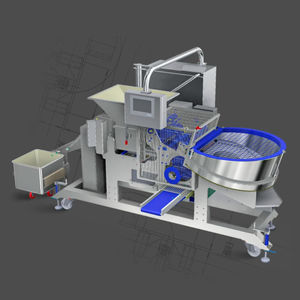

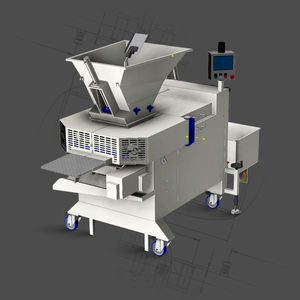

Continuous industrial fryer ECOFRY MY2023vegetablefor snacksmeat

Add to favorites

Compare this product

Characteristics

- Type

- continuous

- Food product

- vegetable, for snacks, meat, for fish, dough products

- Other characteristics

- conveyor, stainless steel, automatic, immersion, thermal fluid, with filter, hot oil pouring, PLC-controlled

Description

SAVES 25% OIL COMPARED TO ANY OTHER FRYER

The first automatic, continuous frying solution that reduces oil use by 25%.

The only one in the world to have the vertical fin heat exchanger integrated in the conveyor belt, an oil filtering system down to 10 microns and a washing system integrated in the machine body.

This ensures constant oil temperatures throughout the cycle and enhances frying uniformity and crispness.

It can fry products both on the surface and by immersion thanks to a system of belts that accompany the products all the way through.

The revolutionary washing and opening system enables rapid and thorough sanitisation, allowing easy separation of its constituent elements for impeccable cleaning.

It can be integrated with the industrial information system: it detects, processes and sends production process data in real time.

Thanks to this function, you can immediately detect technical problems and receive assistance even remotely, reducing costs, delays and interruptions in production.

-25% less oil thanks to integrated heat exchanger in the conveyor belt

-Integrated paper oil filter

-Input belt with adjustable inclination

-Stainless steel oil pump

-Electronically liftable hood

-Stainless steel IP69K hygienic motors (optional)

Catalogs

ECOFRY MY2023

1 Pages

Related Searches

- Stainless steel cooking unit

- Steam cooking unit

- Meat forming machine

- Automatic meat forming machine

- Industrial fryer

- Patty meat forming machine

- Pasta industrial cooker

- Meat industrial cooker

- Batch industrial cooker

- Automatic industrial cooker

- Vegetable industrial cooker

- Continuous industrial fryer

- Sauce industrial cooker

- Single-tank industrial cooker

- Cream industrial cooker

- Vegetable industrial fryer

- Industrial cooker with cooler

- Conveyor industrial fryer

- Jam industrial cooker

- Meat industrial fryer

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.