- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

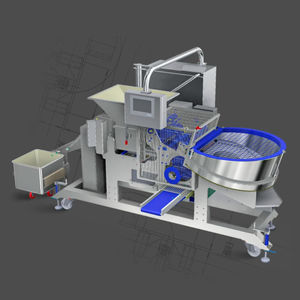

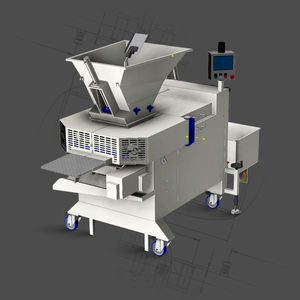

Multi-layer product food industry production line SRATIMATIK MY2023automatic

Add to favorites

Compare this product

Characteristics

- Finished product

- for multi-layer products

- Other characteristics

- automatic

Description

the world's only system for multi-layer products.

This is an automatic line designed by MTS for the production of multi-layer meat, sausage and cheese products.

This machine is equipped with a precise cutting system that allows a very wide range of raw materials to be processed, regardless of consistency and composition.

The multi-layer production line performs clean cuts with uniform thicknesses without any unsightly tears or tears in the product and overlaps the layers one on top of the other.

In addition, it is equipped with a special product transport system that allows the use of even extremely soft and tender raw materials.

This machine is ideal for producing products such as cordon bleu, toast, sandwiches, mozzarella in carrozza and Valdostana with a perfect shape.

The machine has a modular composition: the accurate design and easy accessibility of the various processing elements not only optimise production capacity but also simplify cleaning and maintenance.

-Production capacity of up to 3000 finished products per hour

-Conveyor belt of 400, 600 and 1000 mm

-Precision pneumatic filling positioning

-Fitted with a cream dispenser (optional)

-Adjustable slice thickness from 0 up to 15 mm

-Modular slice width and thickness up to a maximum of 500 mm in length and 120 mm in width

-Adjustable feed speed of product and cutting blades

Catalogs

No catalogs are available for this product.

See all of MTS srl‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.